Advanced Hose Technology

Advancement in hose technology fuels quality hose solutions

At Flextech, we know that repetitive, arduous applications demand high-quality and durable hoses to ensure optimum performance and this is where using advanced hose technology comes in.

Hose Production

At Flextech we operate a technologically modern, safe and efficient, purpose built hose production facility. We have the ability to manufacture high quality PTFE, hygienic silicone and rubber, hydraulic hose assemblies and much more. We also keep our warehouse constantly stocked with products including coiled hose, flexible ducting, thermoplastics, couplings, fittings and many other popular accessories in order to offer a Next Day delivery service for hundreds of items.

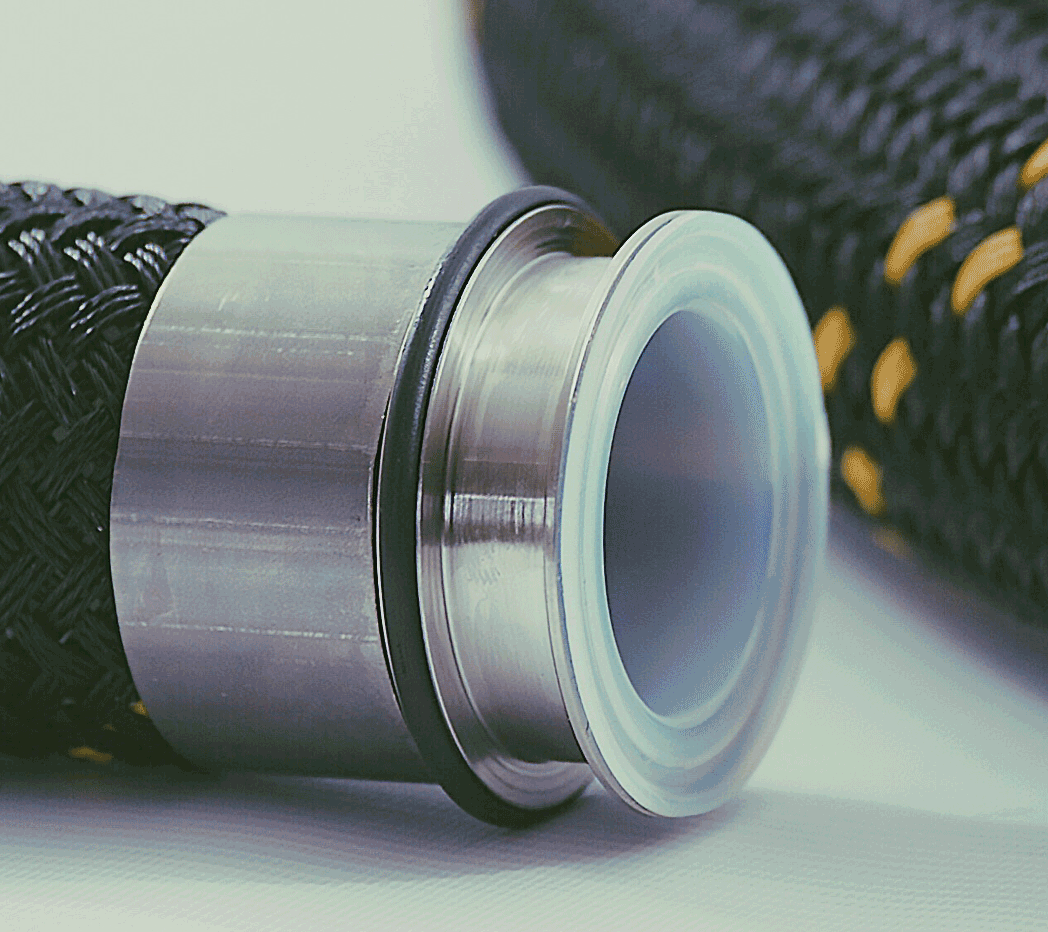

Tafting/Flaring of PTFE

PTFE is an amazingly malleable material which you can do so many things with! One thing we’re great at doing with PTFE hose assemblies at Flextech is tafting. This involves extruding the liner over the external face of an attached fitting to ensure all wetted parts are PTFE lined.

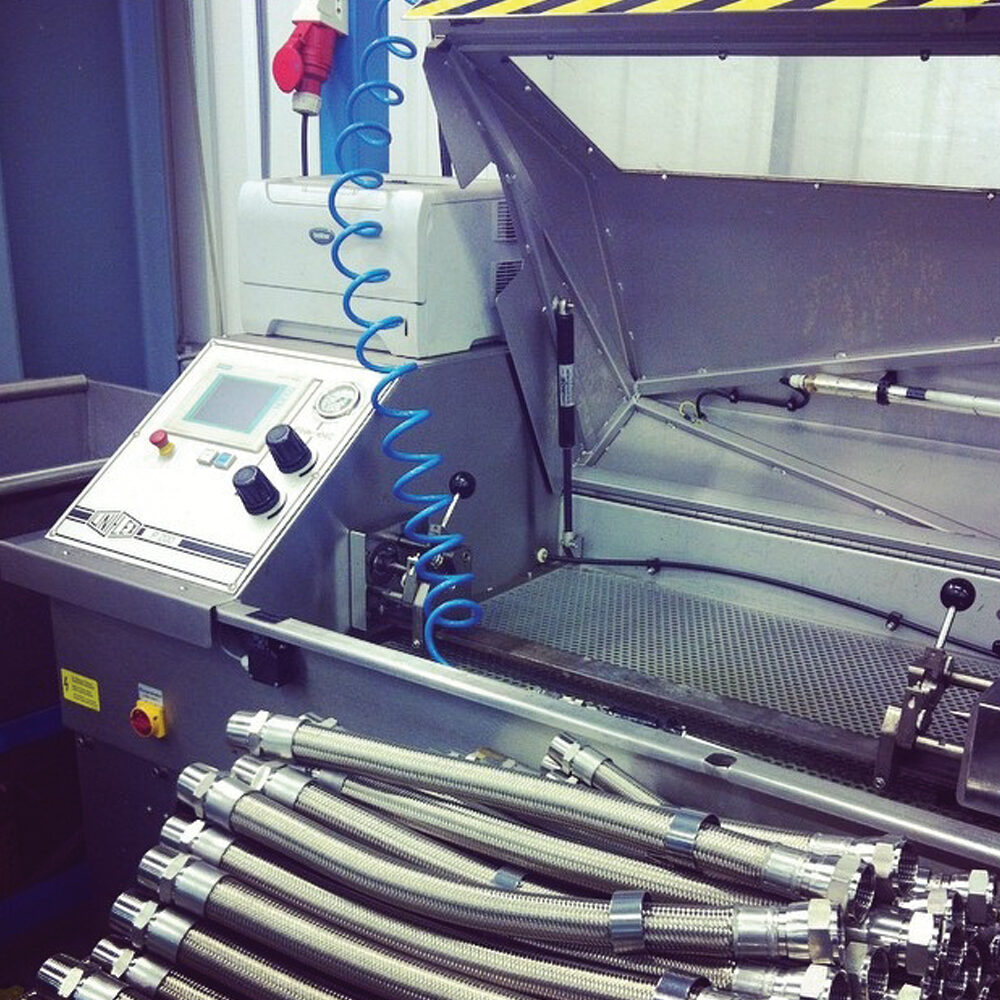

Hose Swaging

We can externally swage permanent end connections to PTFE, Rubber, PVC, Silicone, Hydraulic and Composites from 3mm (1/8”) to 200mm (8”) in diameter. Our swaging process allows us to offer a substantially tougher application attachment for securing products while they operate under pressure whilst simultaneously providing a much safer connection. Swaging hoses with Shawlok end connections enables them to meet much higher working pressures and reduces traditional and common coupling failures that occur with un-swaged hoses.

Extruded Silicone Hose Manufacture

Our USP Class VI grade, platinum cured Pharmaflex, PharmaSil and Pharmafluor silicone hose assemblies use a manufacturing process that allows them to be formed from one piece of material and extruded. Pharmaceutical applications have stringent hygiene requirements which are glorified through this manufacturing method.

PTFE/FEP Lined Rubber Hoses

By combining PTFE hose as a liner and rubber hose as a cover Flextech are able to supply a high performance range of hose assemblies for specialist applications, offering the best of both worlds.

Etching and Engraving

At Flextech we have the facilities to engrave, laser or chemical etch product batch details, traceability numbers, date of manufacture, part codes for identification, company name etc onto your hose. In essence, we can put anything you would like onto the ferrules or identification collar.

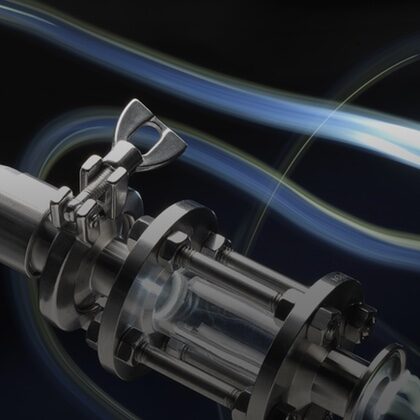

Hose Testing

At Flextech we take the safety of our customers, staff and general public very seriously. Hoses under pressure can fail in service causing severe injury if they are not correctly assembled or installed. It is for this reason that we have destructive and non-destructive testing procedures to ensure the integrity of each hose under pressure. We operate a technologically adept automated pressure testing equipment that is capable of running bespoke test cycles with recorded test results to ensure safety and peace of mind.

3.1B Material Traceability

At Flextech we believe in manufacturing and providing truly fit for purpose hose solutions that are of an outstanding quality. We operate a full batch traceability system for all stainless steel machined components and hose compounds used in the manufacture of our Hygienic hose assemblies. We do this so that you know the true quality of what you have bought from us down to the finest of details and smallest of components.

Advice & Consultation Capabilities

We can help you by offering sound advice, design suggestions, product development (for specific hose applications) or just to point you in the right direction. With nearly 40 years of development in our understanding of technical knowhow, application requirements and quality assurance you can be assured of our ability to deliver optimal hose solutions.

Flextech help our customers to:

- Solve their hose problems

- Reduce production and engineering downtime

- Improve manufacturing capabilities

- Advise on hose material, quality, application & safety issues

- Design bespoke hose solutions

- Laser mark hose collars with identification & test details

- Provide our refurbishment facility to reduce your costs

- Arrange site surveys & audits such as hose inspection, asset management and health & safety

- Advise on stock holding & call-off

Our Standards and Certifications

BRCGS Partnership

BRCGS, previously known as BRC (British Retail Consortium), has evolved into an essential brand and consumer protection entity. As "Brand Reputation Compliance Global Standards," BRCGS is embraced by more than 29,000 certified suppliers across 130 countries. Certification is granted through a worldwide network of accredited certification bodies. BRCGS' Standards establish uniformity in quality, safety, and operational benchmarks, assuring manufacturers' adherence to legal responsibilities and ensuring consumer safeguarding. Presently, certification according to BRCGS' Standards is frequently a fundamental prerequisite for prominent retailers, manufacturers, and food service establishments.

Working in partnership with BRCGS, Flextech hereby confirm that the following hose ranges:

- Brewflex® Butyl lined brewery hose

- Dairyflex® NBR lined food & dairy hose

- Multiflex™ EPDM lined food & beverage hose

- Pharmaflex® Silicone food & pharma hose

- Convoflex™ PTFE lined food, beverage & pharma hose

Conform to the following standards for use in Food and Drink manufacturing markets

- FDA 21 CFR177.2600

- BfR D.M.21/03/73

- ADI free

- EC 1935/2004

- Phthalate free

- 3-A Sanitary Standard

- USP Class VI (Pharmaflex® only)

- EU Pharmacopeia 3.1.9 (Pharmaflex® only)

All products manufactured and supplied by Flextech Hose Solutions Ltd are done under our ISO 9001:2015 approved Quality Management System.

ISO 9001

The Flextech commitment to providing high quality products is reflected in our ISO 9001:2015 Quality Management System. The stringent quality control procedures in place ensure that integrity is maintained at every stage of production. We utilise high grade materials and components in the manufacture of our hose products. Machined and cast fittings include Stainless Steel (304,316,321) Brass, Copper, Gunmetal, Aluminium, & Titanium with full material certification available upon request.

Our products are certified to EN 10204:2004 and meet API, BS, DIN, FDA, ISO and many other international standards. We operate a modern, safe & efficient purpose-built hose production facility.

We have the benefit of 6 streamlined hose assembly lines:

- PTFE smooth and convoluted bore hose assemblies

- Hygienic silicone and rubber hose assemblies

- Hydraulic hose assemblies.

ISO 14001

Environmental issues have become very significant in recent years and as a leading company in its field Flextech has proven its commitment to put in place procedures and working practices that will allow it to further control and monitor the effects of its activities on the environment.

We operate to ISO 14001 standards which provides customers and employees alike with the assurance that Flextech’s environmental performance meets and will continue to meet, its legal and environmental policy requirements. This statement covers all aspects of the company’s activities and our management team monitors National, European and Global environmental legislative developments to ensure our compliance before they become law.