Our Brands

Our Brands… the story

Flextech’s mission is to pioneer hose assembly innovation and asset management solutions.

Flextech was founded in 2009 by a group of engineers who wanted to prove that people didn’t need to compromise in order to obtain a hose that met their requirements – that hose assembly solutions can be high quality, fit for purpose, and appropriately priced. Today, Flextech builds not only fit for purpose hose assemblies but also provides complete hose register maintenance programmes. Flextech believes the faster companies stop relying on cheap, quality compromised hose imports and move towards a fully traceable, responsible hose assembly register system, the better.

Launched in 2012, both Brewflex & Dairyflex hose assemblies unveiled Flextech’s technological understanding of hose, their components and intended application use. By designing with not only the application in mind, but also the experience of the user, we revolutionised the terms ‘brewery hose’ and ‘dairy hose’ by expanding the ranges to suit different environments. We’ve created crush proof hoses for arduous environments, extra-flexible hoses for space restricted environments – both complimenting the standard range of suction and delivery hoses available in each industry. The result? We now supply around 400 out of 2000 UK breweries, and a growing number of dairies in the UK too.

From there, Flextech designed Pharmaflex, a platinum cured silicone hose with an extruded liner that meets USP VI and EU Pharmacopeia requirements. It was the most hygienic hose we’d yet created – meeting some of the world’s most stringent standards prominent within the pharmaceutical, bio-medical and life science industries. The Pharmaflex range can be found in Big Pharma throughout the world on things such as filling machines, dispensing units and production lines.

In 2015, Flextech expanded its product line with tafted PTFE hose assemblies, something only three other companies in the UK can do to the same standard as us. We manufacture a unique set of hose assemblies from PTFE liners such as; smoothbore, convoluted, easycrimp and castellated, enabling niche businesses with unique application requirements access to hoses that won’t just do a job well, they will meet the applications needs entirely.

All of Flextech’s hose assembly solutions are produced at its factory in Slough, United Kingdom, with the vast majority of the components coming from the UK or the EU. To achieve our goal of offering total hose solutions, Flextech is taking a proactive approach to understanding application requirements and potential hose solution compatibility. And in order to complete our entire hose solutions ecosystem, Flextech is able to source and supply a diverse range of; fluoropolymer hoses, silicone hoses, rubber hoses, thermoplastic hoses, metal hoses, flexible ducting, hydraulic hoses, composite hoses, hose reels, couplings and fittings as well as associated accessories.

And this is just the beginning. With Flextech determined to venture further out into the frontier that is, specialist hose applications, we’ll continue to invent new brands and products which can satisfy niche requirements with fit for purpose hose solutions. Hose and application knowledge already exist independently, but when combined, they become responsible business solutions – that’s what we are about.

Discover more below

High Quality Dairy & fatty Foodstuffs Hose Range

Dairyflex®

High Quality Brewing Hose Range

Brewflex®

Platinum Cured Silicone Hose Range

Pharmaflex®

Convoluted, Smoothbore, Castellated and Easycrimp PTFE Hose ranges

PTFEflex™

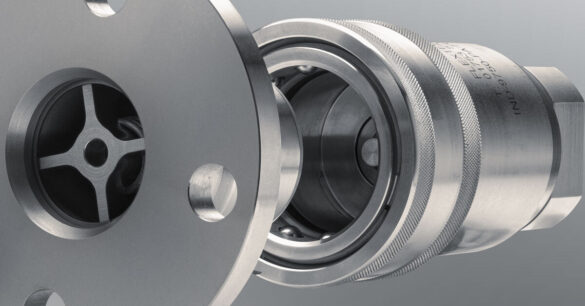

Aviation Hydrant Couplings

SelfVent™ Couplings

Thermoplastic Suction Hoses

Flexhose™ & FlexVac™

316L Stainless Steel End Connections Range

Shawlok™