Specialised suppliers of

High Quality Flexible Ducting

Specialist Ducting

Welcome to a world of industrial engineering excellence with Flextech. We provide a comprehensive range of flexible ducting solutions for engineers, end users, OEMs, MROs, and resale companies worldwide. Our Ducting solutions offer limitless possibilities for industrial applications.

About Our Flexible Ducting's

At Flextech, we are more than just a hose supplier – we are your partners in engineering success through fit for purpose ducting solutions. Our product range, facilities, expertise, and unwavering commitment to quality allows us to offer flexible ducting that encompass an array of materials, types, and sizes. Our flexible ducting stands at the centre of modern airflow and extraction management, offering adaptable, durable, and effective solutions for industrial applications.

What is flexible ducting?

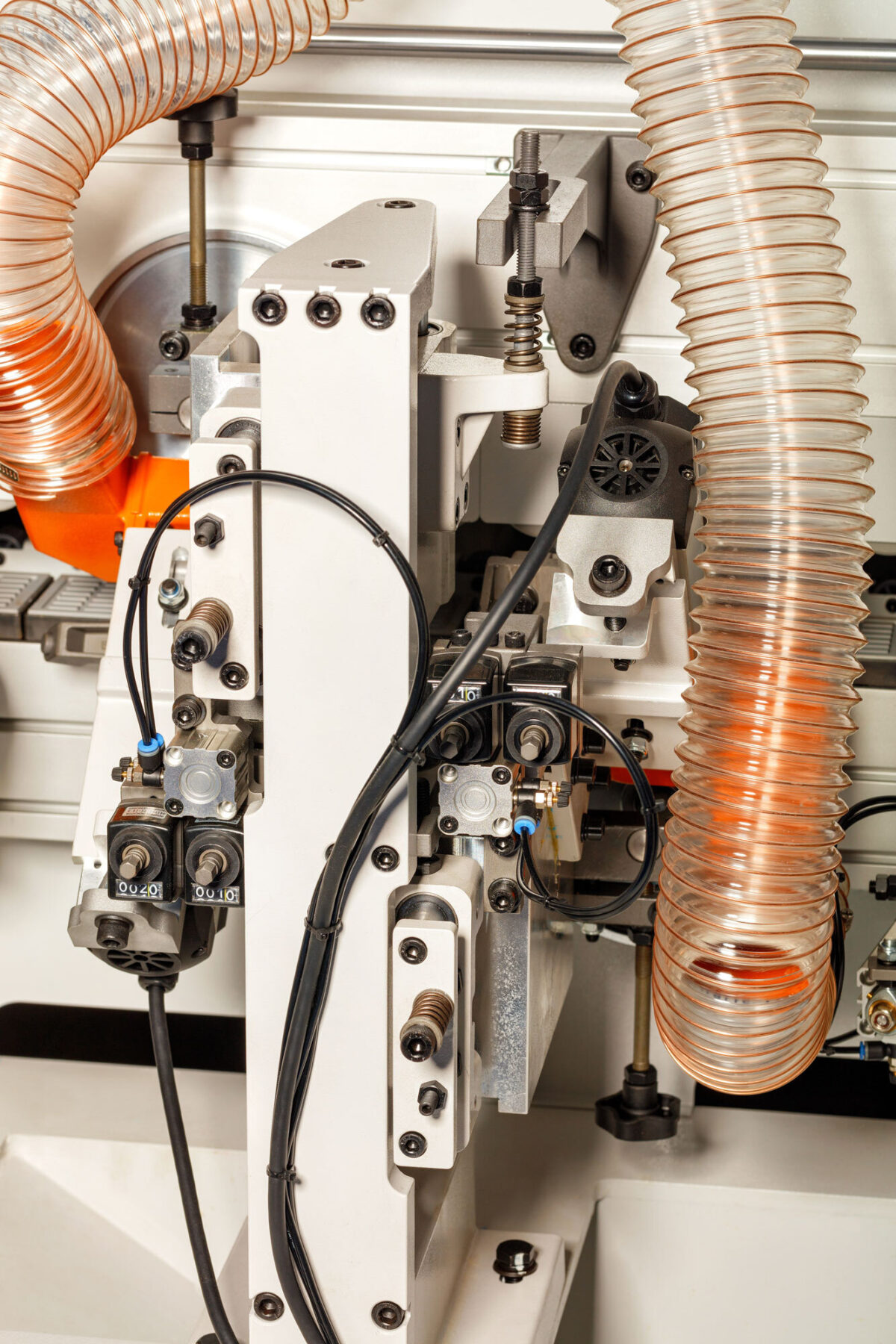

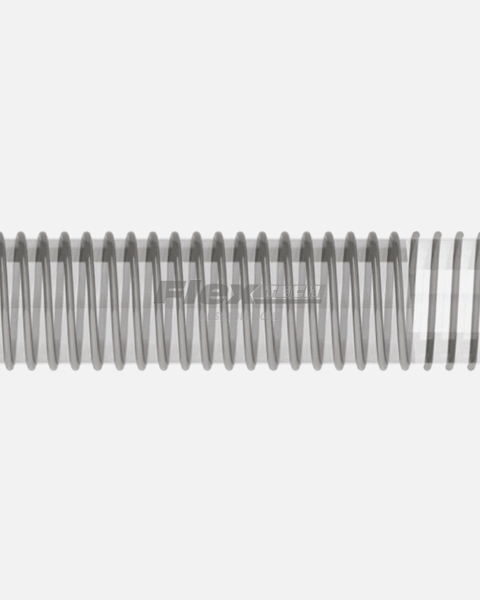

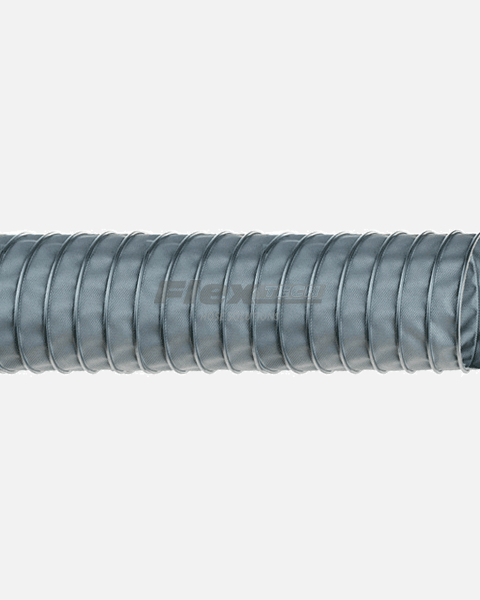

Flexible ducting is a conduit composed of a tape or profile extrusion joined around a supporting spiral helix which can be used to link different components and systems within industrial systems. This includes the conveyance of air, gases, fumes, and other solids, while its design allows a high degree of flexibility and ensures smooth flow of any media. With a wide variety of materials, each tailored to excel in specific environments, flexible ducting offers unparalleled adaptability for the widest range of applications.

We offer ductings for suitable temperatures ranging between -85°c to +1100°c across a multitude of industries.

Types of ducting available include, but are not limited to:

- Neoprene, Silicone, PVC, Polyurethane, TPR, LDPE, EVA, CSM/Hypalon, PTFE: Materials designed with specific properties, from chemical resistance to high-temperature tolerance.

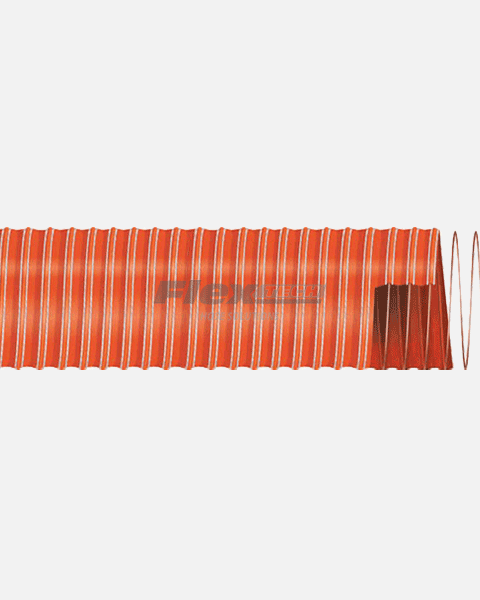

- High Temperature Fabrics: Insulating properties, fire resistance, ideal for extreme conditions.

- SBR/EPDM Ducting: Resistant to weather and ozone, perfect for outdoor applications.

- Specialist Ductings: bespoke solutions for unique industrial processes and applications.

Advantages of flexible ducting

Flexibility, Versatility, Quality - The Pillars of Our Flexible Ducting Solutions

- Lightweight: Flexible ductings have a lightweight construction and many can be axially compressed making them easy to install and store.

- Highly flexible: Their design makes them extremely flexible.

- Durability: Engineered for longevity, our ductings withstand the rigors of industrial environments, from extreme temperatures to abrasive substances.

- Low Maintenance: With good resistant to corrosion and wear, these ductings require minimal upkeep, reducing downtime and costs.

- Versatile Applications: From automotive and aerospace to chemical processing and material handling, the possibilities are limitless.

What can you use flexible ducting for?

Industries, Marketplaces, and Applications include:

- Industrial: For exhaust and fume extraction systems.

- Chemical Processes: PTFE and Hypalon® ductings for transporting aggressive gases & chemicals safely.

- Pharmaceuticals: Air handling in cleanroom environments and handling dust and powders.

- Woodworking and Metalworking: For efficient dust and debris extraction.

- HVAC: For ventilation and air movement systems.

- Materials Handling: Heavy walled PU ductings for conveying abrasive materials.

- Vacuum applications: Industrial cleaning applications.

- High temperature applications: Exhaust systems, engine test beds, gas extraction.

- ATEX & Electrically conductive: Polyurethane, TPR, PVC and more. Ductings can be grounded via earthing their wire spiral.

View Some of Flextech's Flexible Ducting

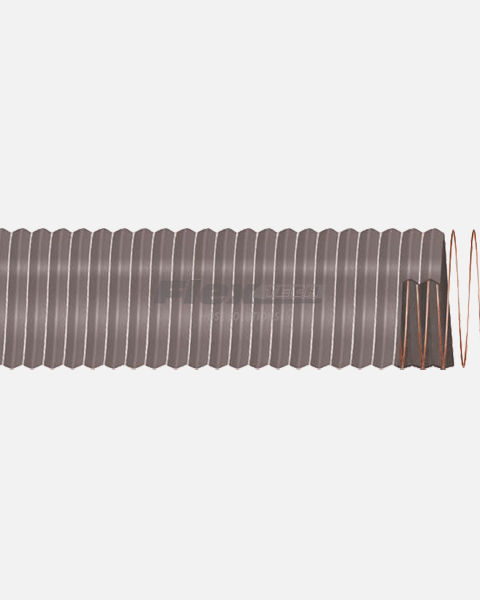

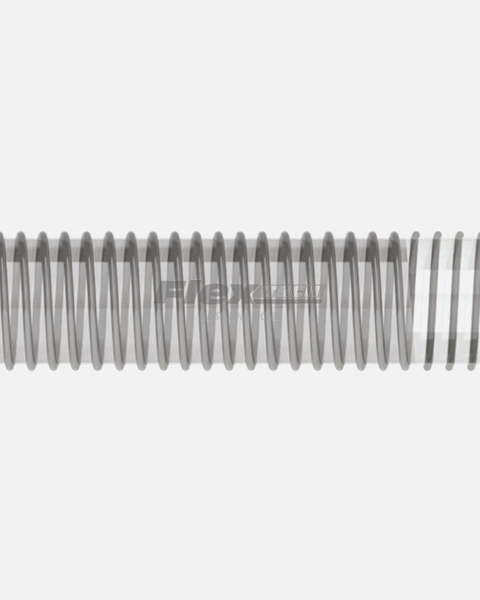

T3100N1 | Unlined Neoprene Ducting

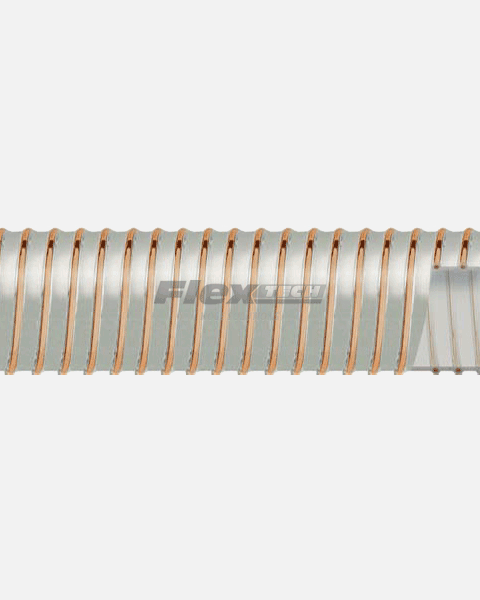

T3150B | Lined Silicone Ducting

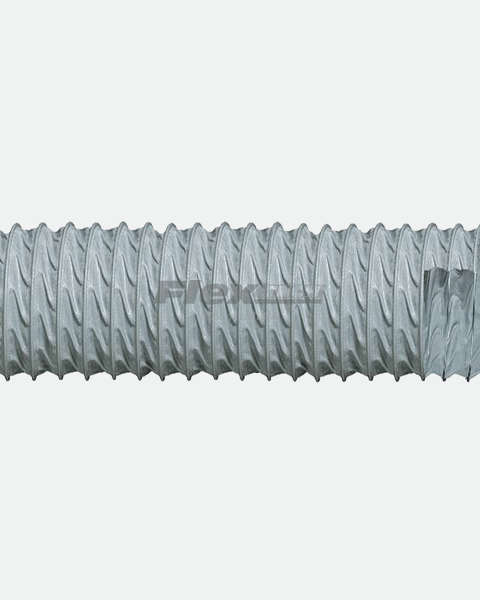

T3200B | Plastiflex Vacuum Ducting

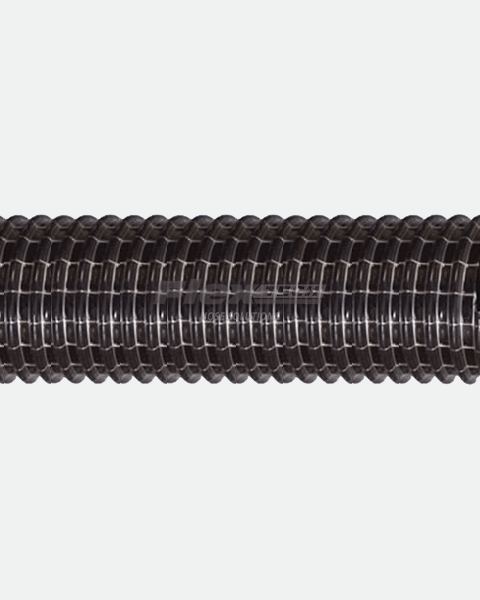

T3300 | Superflex Polyurethane Ducting

T3300-AS | Superflex Polyurethane Ducting (Antistatic)

T3320-PU04 | Vacuflex Polyurethane Ducting

T3320-PU06 | Vacuflex Polyurethane Ducting

T3650 | Glassflex Ducting

T3800SU | Superflextract PVC Ducting

T3845-PVC6E | Vinylflex Mediumweight PVC Ducting

T3930-0400 | Exhaust Gas Ducting

T3910-PLS | Specialist PVC Ducting