Pharmaceutical, Bio-tech, Life-Sciences, Cosmetics

Pharmaceutical Hose Assemblies

Our ranges of Pharmaflex™, PharmaSil™ and Pharmafluor™ Hoses are some of the highest specification products we offer. They have been designed to meet many international and domestic standards and are suitable for even the most niche of pharmaceutical, bio-medical or life sciences applications. These, alongside PTFE hose assemblies, form the core range of solutions we offer for these marketplaces and their applications

Key features

- Biopharmaceutical grade

- Excellent bend radius

- Smooth seamless extruded liner

- Autoclavable and sterilisable

- Suitable for sterlisation with steam, argon and cobalt

- Tasteless and odourless

- Phthalate free

- Platinum cured

- Compatible with SIP and CIP regimes

- High transparency, no yellowing

- Excellent mechanical properties

Standards, Accreditations & Registered Compliances

- ISO 10993-6, IS0 10993-10, ISO 10993-11 biological evaluation of medical devices

- ISO 9001:2008

- EU ResAP 2004 (4), CE 1935/2004, Reg 10/2011/ECC

- European Pharmacopoeia 3.1.9

- BfR hose material recommendation XV

- BGA Class XV

- FDA CFR 177.2600

- USP Class VI biological reactivity test, in vivo

- USP XXIV (87) biological reactivity, in vitro

- USP XXIV (88) biological reactivity, in vivo

- Meets and exceeds 3A sanitary approval

- GB/T 21928-2008

- France – Journal Officiel Brochure 1227

- Germany – BGWYVA LIIA

- Italy – Gazetta Ufficiale – 1973

Pharmaflex™ medical and pharmaceutical grade silicone hoses are ideally suited for suction and delivery applications within the pharmaceutical, biotechnology and life sciences industries such as feeding pumps, drug dispensing equipment, diagnostic equipment and processing equipment.

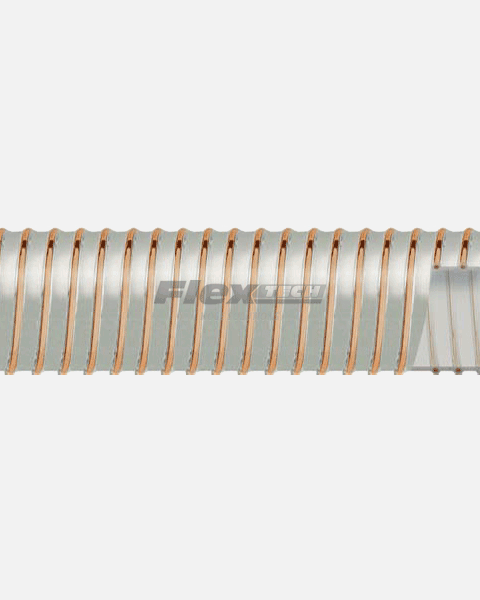

The construction of these hoses allows them to work efficiently and effectively on applications at working pressures and temperatures other hoses would not be able to operate within, with resistance to temperatures from -60°C to +200°C and pressures up to 16 bar. These pharmaceutical hoses can be reinforced with steel coils or polyester braids in multiple layers to provide flexibility, versatility and value.

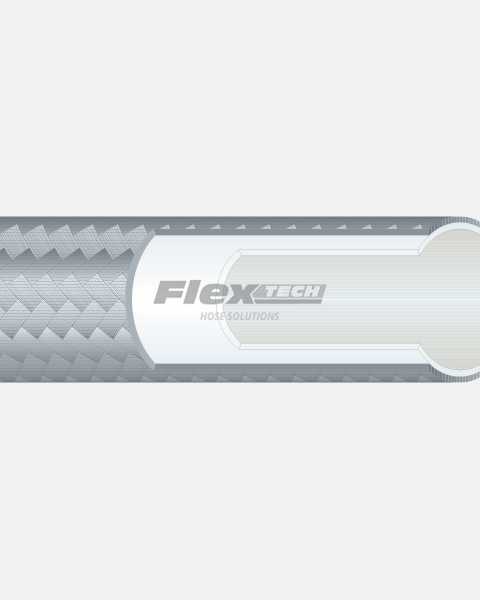

Pharmasil hoses feature smoothbore extruded liners, smooth covers and a high purity (USP VI) platinum cure. This makes them ideally suited for a variety of low pressure applications as they can resist temperature extremes, radiation, compression sets, weathering, chemical attack, corona and ozone as well as being odourless and tasteless. With internal diameters of 1/4″ to 1″ and a range of colour options and end fittings, these hoses can be manufactured to your exact requirements.

These hoses are produced in one of the most versatile and flexible FED STD 209E Class 10,000 Clean Room manufacturing facility in Europe, using procedures controlled by ISO9001:2008 standards. Clean Room conditions are continually monitored to ensure a Class 7 standard is maintained. The production facility used only produces Platinum Cured Silicone products ensuring there is NIL cross contamination. Pharmaflex Silicone Tubing is packaged individually in double wrapped heat sealed polybags and then placed in a clean, white box ready for despatch.

Some of Flextech's Pharmaceutical Hoses

T4201 | PHARMAFLEX® Pharmaceutical Suction & Delivery Hose

T4205 | PHARMAFLEX® Pharmaceutical Delivery Hose

T4210 | PharmaSil™ Braided Silicone Hose

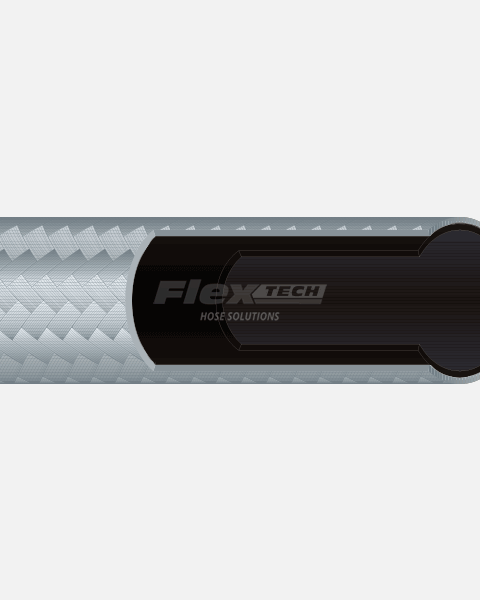

T6100 | PTFE Lined Hose Assemblies

T6110 | FDA Antistatic PTFE Hose Assemblies

T6400 | Convoluted PTFE Hose (Teflon®)

T3350-3218 | Food & Pharma Polyurethane Ducting

Triclamp Hygienic Hose Tail Fittings