Metallic Hose Assemblies

Metallic Hose Assemblies

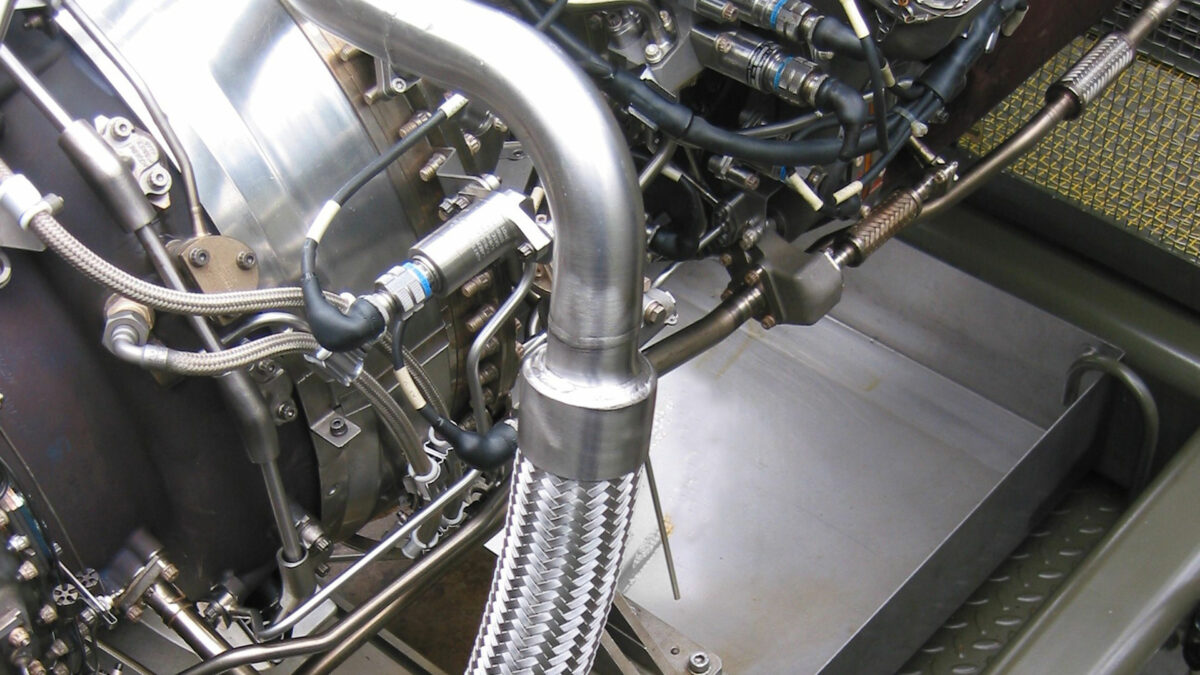

Flextech’s flexible metallic hose assemblies are designed to meet the stringent temperature, pressure and vacuum service requirements found in a huge array of applications. Manufactured from high grade, flexible stainless steel, they also offer unique properties which include excellent chemical resistance and high temperature resistance.

About our metal hose assemblies

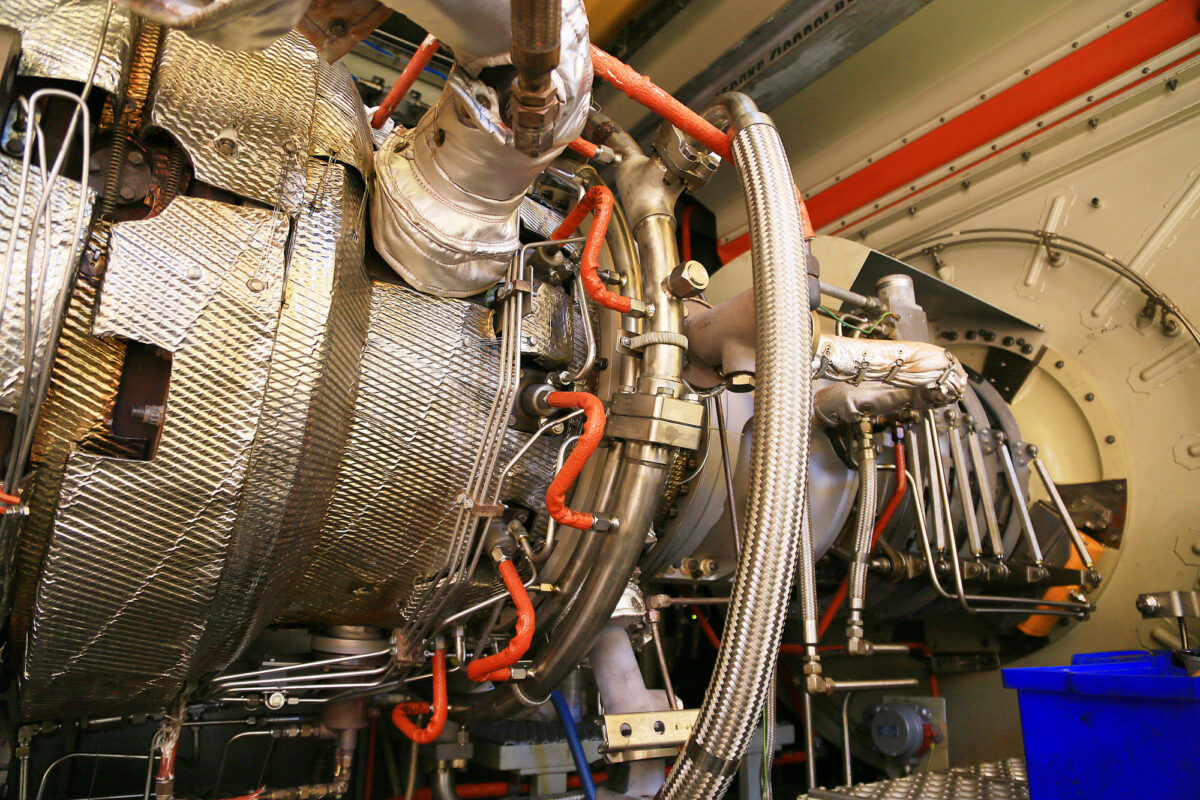

Our metallic hose assemblies are built to withstand the most challenging environments and demanding applications, where a general rule is to use a metallic hose when no other hose type will do. Flexible metallic hoses perform well in applications with extreme conditions or variables such as temperature extremes, diverse chemical compatibility or concerns around permeation. Offering good durability properties and resistance to corrosion, metallic hose assemblies have become indispensable components in industries such as oil and gas, automotive, aerospace, pharmaceuticals, and chemical processing. At Flextech, we take immense pride in our expertise in these exceptional hose assemblies, delivering products that promise reliability, safety, and unmatched performance for a wide range of industrial needs.

Metallic hoses have limited flexing cycles and are not generally suitable for applications with excessive vibration.

What is a metallic hose?

Metal hoses, also known as metallic hoses, metal hose assemblies or metallic hose assemblies, are flexible conduits used for the transfer of liquids and gases in various industrial applications. Metal hoses are constructed from high-quality stainless steel varying in grades from 304 to 321 and 316 as well as other alloys such as Inconel®, Incoloy®, Monel®, Titanium and Hastelloy®.

The working temperature range and pressure ratings of metal hoses depend on various factors, including the materials used, construction, and size. In general, metal hoses can withstand a wide temperature range, typically from -200°C (-328°F) to 600°C with a peak of 800°C (1472°F) or higher, depending on the specific alloy. As for pressure capabilities, the pressure capacity is influenced by the hose's construction, diameter, and the materials used. Metal hoses are capable of handling varying levels of pressure, ranging from 0-200+ bar.

Advantages of Metallic Hose Assemblies

Some key features of metallic hoses that make them a reliable choice include but are not limited to:

- Exceptional Durability: Metallic hoses are constructed from high-quality stainless steel or other robust alloys, making them highly durable and resistant to corrosion, and abrasion.

- High Temperature Resistance: Can withstand extreme temperatures, ranging from cryogenic conditions to high-temperature applications.

- Pressure Resistance: Can handle high-pressure applications. An ideal choice for critical systems that require leak-free operation at high pressures.

- Flexibility & Versatility: Metallic hoses offer excellent flexibility however they have a limited number of flexing cycles, typically between 8,000 - 50,000.

- Corrosion Resistance: Can withstand contact with a wide range of corrosive media, ensuring the integrity of the fluid being conveyed.

- Vacuum Compatibility: These hoses are capable of maintaining a vacuum-tight seal, making them suitable for applications requiring vacuum conditions, such as in vacuum pumps and chambers.

- Fire Resistance: Depending on the materials used, metallic hoses can offer high levels of fire resistance.

What can you use metal hose assemblies for?

Typical applications of our metallic hoses are:

- High Temperature Hydraulic Oils in machinery, vehicles and engineering

- Steam, Chemicals and Petroleum products used in manufacturing, construction and energy

- Corrosive liquids & Gases in the chemical and medical industries

- Compressed Air & Pneumatic liners

- Cryogenic applications

- Food & Beverage production

- Nuclear plants and Steam lines

- Fluids associated with high temperature and pressure in paper and fabric plants,

- Specialist manufacturing including Tyre moulds and Textile Machinery

- Oil Refineries and Drilling Rigs / Platforms

- Toxic and corrosive applications.

Flextech's custom metal hoses

Our Metal Hose Assemblies

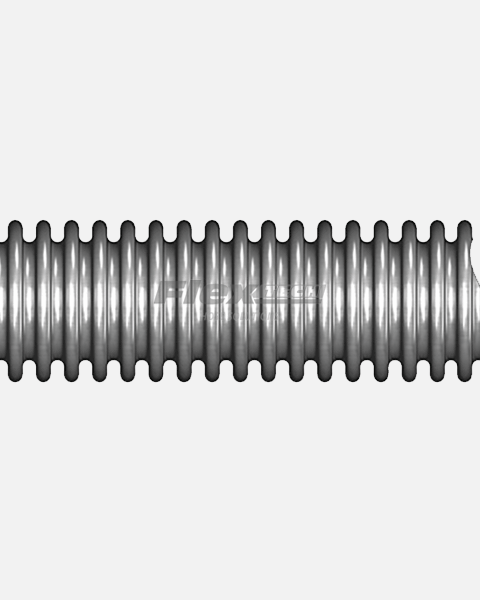

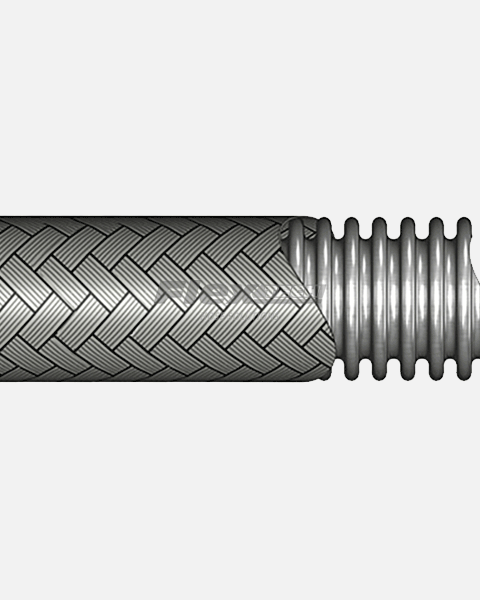

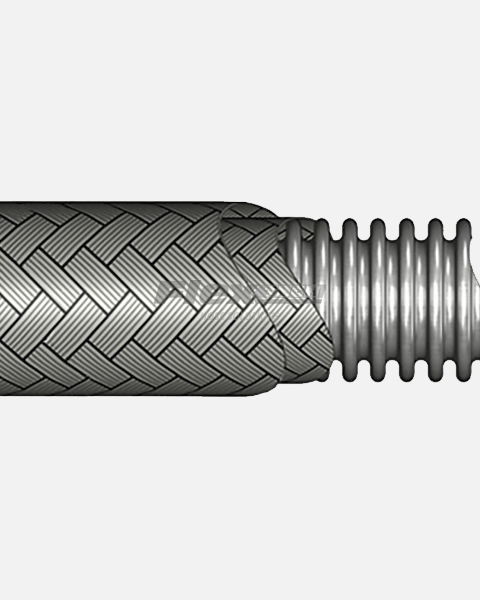

Available as convoluted bore with an assortment of grades, covers & end terminations, our metal hoses are ideally suited for gas supply and transfer of steam, chemicals, food processing, hot water systems, cryogenics and full vacuum applications. Our metallic hoses are able to withstand up to 50,000 flex cycles and are manufactured to ISO10380:2012, the current international standard for corrugated metal hoses and hose assemblies.

With operating temperatures as low as -200°c and as high as +600°c (with a peak point of 800°c in some circumstances), Flextech’s metallic hoses offer performance and reliability in all situations.

Typically, our full stainless steel braided hoses consist of an AISI 321 or 316 grade liner within a 304 or 316 grade stainless steel braid. This braid can be reinforced as a double or even triple braid to increase the pressure rating of the hose for certain applications, or covered in silicone, EPDM, a fire sleeve or flexible insulative material. Internal dimensions for all of our metallic hosing range from narrow 6mm diameter to large bore 250mm diameters. Metallic hose assemblies have a diverse pressure rating range and operate within a 4:1 safety factor. Metallic hoses can also be lined with PTFE, spiralwound hose or internal braiding.

Optional Extra's

At Flextech, in order to meet your applications demands comprehensively, we offer an array of services to compliment and consider each industrial application as they present unique challenges and specific requirements. Our commitment to delivering excellence extends beyond standard manufacturing, and we take pride in offering the following customisation options:

- X-Ray of all Welds: For critical applications that demand flawless weld integrity, we provide X-ray inspection services for all welds in the metallic hose assemblies. This non-destructive testing (NDT) technique ensures that the welds meet the highest standards of quality and safety.

- NDT – Inspection of Welds: Apart from X-ray, we offer other non-destructive testing methods to inspect the welds thoroughly. These NDT techniques include ultrasonic testing, magnetic particle testing, liquid penetrant testing, and more, depending on your specific requirements.

- Hydrostatic Test Certificates: Our hydrostatic testing service guarantees the pressure resistance and integrity of the metallic hose assembly. You'll receive comprehensive test certificates documenting the test results.

- Certificates of Conformity: Flextech provides Certificates of Conformity, validating that our metallic hose assemblies comply with all specified requirements, standards, and regulations.

- Material Certification: For industries with strict material traceability requirements, we offer material certification, assuring you that our hose assemblies are fabricated using materials with full traceability.

- Vacuum Testing: To ensure leak-tightness and performance in vacuum applications, we can subject our metallic hose assemblies to vacuum testing, ensuring they meet performance standards.

- Quality Maps: We provide comprehensive quality maps detailing the manufacturing and inspection process of the metallic hose assemblies, ensuring transparency and accountability.

- Technical Drawings & CAD: Our engineering team can provide detailed technical drawings and CAD models of the hose assemblies.

- Weld Procedure Documents & Welder Approval Certificates: For industries requiring strict adherence to welding procedures, we offer detailed weld procedure documents and welder approval certificates, assuring the competency of our welders.

- Oxygen Cleaning: In applications where oxygen purity is critical, such as in the medical or aerospace industries, we provide oxygen cleaning services to meet stringent cleanliness standards.

- Plating of Assemblies for Specialist Applications: For additional protection or conductivity, we offer plating options such as chrome plating or other specialised coatings, typically for the end fittings rather than whole assemblies, however this can be done.

- Kiln Drying (Oven) : When applications demand specific temperature control and moisture removal, our kiln drying service ensures that our metallic hose assemblies meet the exacting requirements. If your application involves working with hygroscopic materials or requires a moisture-free environment, we offer oven drying services to ensure the hose assembly's readiness for use.