Brewers Beer Hoses | Beer Brewery Hose Brand - Brewflex®

Hygienic Brewery Hoses & Assemblies

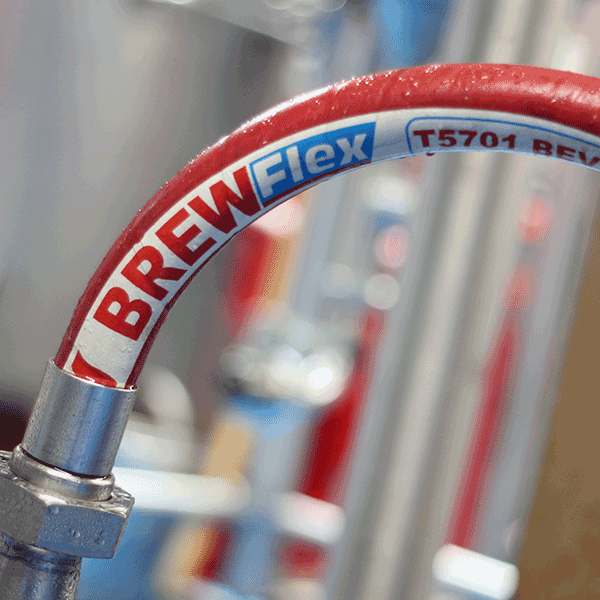

Hygienic, high quality and non-tainting, Brewflex® is the UK’s leading brewery hose.

About Brewflex®

Brewflex® first entered the market in 2010 and is now supplied to over 800 breweries in the UK alone (out of a total 1700). In recent years, Brewflex® has gained a prominent position in the international brewery market, with distribution expanding throughout EMEA—serving breweries across Europe, the Middle East and Africa. This broad reach demonstrates Flextech’s dedication to hygienic hose quality and robust innovation.

In 2017, Brewflex® underwent a significant design update. Enhanced flexibility, durability and long-term integrity have made Brewflex® beer hoses the trusted choice for demanding hygienic brewery operations and global beverage producers.

Brewflex® Details

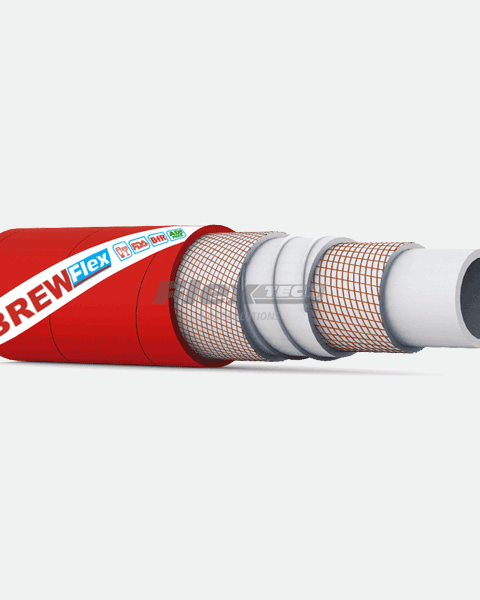

Here you’ll find essential guiding information about Brewflex®—construction, applications, temperature range, and pressure range. Please note, details may vary by Brewflex® model.

- Construction: Odorless, taste-free, hygienic butyl liner, synthetic textile plies and/or steel wire spiral reinforcement, anti-friction EPDM cover. Many models feature rubber hose options for added strength and washdown applications.

- Applications: Beer, wine, cider, perry, spirits (up to 96%), drinking water, fruit juice, soft drinks, and food-grade processes. Brewery hoses are designed to safely handle and transfer these products in food and beverage facilities.

- Temperature range: -40°c to +120°c (CIP cleaning up to +130°c for short cycles). Consistent temperature management protects hose integrity.

- Pressure Rating: 16 bar working pressure & 48 bar burst pressure.

For an overview of all our hose assemblies, see our main hose assemblies page.

Brewery Hose Assemblies, Couplings & Hose Fittings

Flextech offers bespoke brewery hose assemblies built to specification, including hose couplings, hose end connections, and line adapters. 316L stainless steel Shawlok™ hygienic couplings—Triclamp, DIN, RJT, SMS, BSP—are available for brewery hoses, brewers hoses, and beer hose products. Assemblies feature hose fittings and hose clips for secure installation, and flexible rubber hose variants tailored for cleaning or fluid transfer. Dedicated hose brewery solutions cater to installations with long hose line runs or complex pipe fitting needs.

Working Pressure, Temperature & Quality

Brewflex® hoses maintain high working pressure, stand up to frequent cleaning cycles, and perform in wide temperature ranges. The non-tainting butyl liner and robust hose fittings help guard against contamination and product loss, keeping beer and food-grade beverages safe. Flextech is ISO 9001:2015 certified, and each hose offers complete material traceability and FDA compliance for peace of mind. Rubber hose assemblies provide excellent resistance to abrasion and animal or vegetable fats, making them ideal for brewery settings.

Washdown Hoses, Pumps & Brewery Solutions

Brewery washdown hoses, pumps, and flexible rubber hoses are designed for cleaning, transfer, and dispensing in beverage and food industries. Flextech’s product line includes brewery hoses, hose end fittings, and hose reels for streamlined cleaning and technical support. Next day delivery is available across the UK and EMEA for many standard hose assemblies, pumps, and couplings.

Additional Features and Services

- Hose Reels: Specialised hose reels for brewery hoses improve workflow and landing zone tidiness.

- Fittings & Hose Clips: BSP threaded, end fittings, and hose clips for complete hose assembly configurations.

- Rubber Hose Assemblies: Built for durability and chemical resistance, suitable for breweries of all sizes.

- Technical Support: Flextech provides expert product recommendations and STAMPED selection for size, temperature, pressure, ends, and delivery rate—ensuring your brewery hose solution matches your needs.