PTFE hoses | PTFE hose assemblies

High quality PTFE lined hose assemblies

Flextech Hose Solutions design, manufacture and supply high quality custom built, flexible PTFE lined hose assemblies, also known as Teflon® or Polytetrafluoroethylene hoses. Our comprehensive range of PTFE hose assemblies are custom made to meet the stringent temperature, pressure and vacuum service requirements found in food, beverage, pharmaceutical, medical, petrochemical and high pressure gas applications.

About our PTFE hoses

The Teflon® PTFE compound offers unique properties which include excellent chemical resistance, high temperature resistance (from minus 60°C/76°F up to 260°C, 500°F), high working pressure rating (up to 552 bar) and a frictionless, easy clean surface.

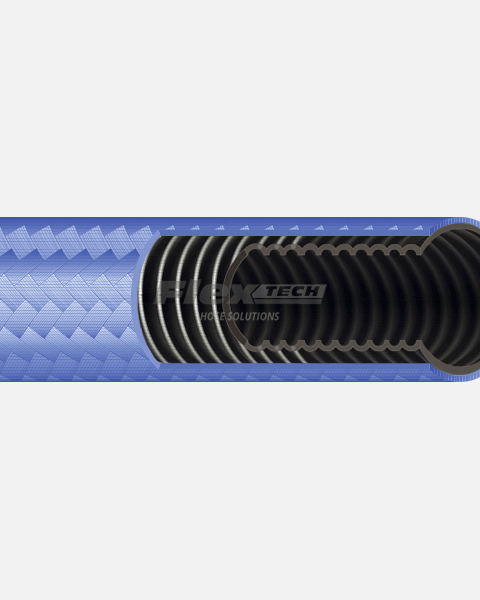

Our PTFE hoses are available in smoothbore or convoluted bore with an assortment of grades, covers & end terminations. The compounds are manufactured from DuPont granules in translucent virgin PTFE to FDA 21.CFR.177.1550 or Anti-Static black PTFE to FDA 21.CFR.178.3297 compliance.

What is a PTFE hose?

A PTFE hose assembly is lined with Teflon, also known as Polytetrafluoroethylene, with specific end connectors attached. Our comprehensive range of PTFE hose assemblies are made to meet the stringent temperature, pressure and vacuum service requirements found in food, pharmaceutical, medical, beverage petrochemical and dairy product applications.

The PTFE compound offers unique properties which include excellent chemical resistance, high temperature resistance (from minus 60°C/76°F up to 260°C, 500°F), high working pressure rating (up to 552 bar) and a frictionless, easy clean surface.

Advantages of PTFE hose assemblies

- Inert to virtually all chemicals

- Very resistant to weathering

- UV light resistant

- Oxidisation resistant

- Resistant to ageing, discolouration and ageing

- Non-flammable

- Lightweight

- Superior flex fatigue life

- Low permeability

- Lowest coefficient of friction of any solid material

- Unlimited shelf life

- Solvent Resistant

What can you use a PTFE Hose for?

- Fluids associated with high temperatures

- Compensation of vibrations and pip work misalignment within a product line

- Fluids associated with pharmaceutical and biomedical transfer and production

- Food handling and production

- Production of dairy products

- Bottle filling

- Beverage service, handling and production

- Petrochemical and specialist chemical transfers

- De-ionised water transfer

- Conveyance of cosmetic solutions

Custom PTFE Hose Assemblies

We can manufacture your PTFE hoses to any combination of lengths, bore sizes from 1/8” to 4”, grades for all industries, covers from stainless steel braid to polypropylene, EPDM or Silicone. The hoses can be reinforced to your requirements, with vacuum wire or single, double or triple braid and fitted with a versatile selection of end terminations. Options include a simple male or female connector at each end, sophisticated compression fittings, Camlock couplings, Dry disconnects, valves and air pressure fittings.

Optional extra's for customisation to enhance application suitability include things such as;

Tafted Ends (Flared)

A tafted, or flared, PTFE hose assembly refers to hose assembly where the PTFE (polytetrafluoroethylene) hose has been flared over or shaped to the face of an end connection. The flaring process involves expanding the end of the hose, creating a smooth, seamless transition from the inside diameter of the hose to the outer diameter of the face of the end connection to ensure all wetted parts are covered. Flared PTFE hose assemblies are often used in applications where chemical compatibility or hygiene are of utmost importance.

Platinum Cured Silicone Cover

Platinum cured Silicone covers conform to USP Class VI are supplied in assortment of colours suitable for temperatures up to +200c and provide a smooth easy clean surface which can be used for either hygiene purposes stopping the external braid of the hose from gathering dust and dirt particles from its environment or to insulate the temperature of the hose to stop operators burning their hands.

TPE (Polyurethane) Cover Options

TPE (polyurethane) is an abrasive resistant cover used to protect the outer braid of the hose becoming damaged whilst providing protection from dust and dirt particles. It also provides a smooth surface that is easily cleanable. Cover is extruded and pin-pricked. Standard colour is black, but other options are available upon request and subject to MOQ's.

Shrink Sleeve

There are various types of shrink sleeve available, all dependent upon application, which enable the product to be wiped down and cleaned easily, as well as providing the external braid from environmental hazards and stop dirt and dust getting in between the braid. Shrink sleeves are available in materials such as; PVC, FEP and Polyolefin dependent upon customer preferences and application criteria.

Bend Restrictors

A strip wound conduit used as a bend restrictor by fitting 300mm length to the end of the hose to limit over bending or used as a full length hose guard to protect the external cover and increase the life cycle of a hose which is generally used on the floor and being dragged around the factory or yard. Option for full-length strip-wound cover available too.

Scuff Rings

A circular ring made of NBR/PVC compound are positioned every 150 to 300mm apart to ensure the hose outer braid does not contact the floor. Available for hose sizes from 1” up to 4” bore these rings are a perfect option for keeping the hose assembly lighter than if it were rubber covered.

Silicone Sponge Insulation

Silicone sponge insulation provides thermal insulation, reducing heat loss and enabling hoses to be handled easily whilst eliminating external condensation forming, and each hose assembly is finished with either a braided or smooth silicone cover. This option reduces the overall flexibility of the inner hose by around 25% and increases the overall hose OD by between 25 to 35mm.

Fire Sleeve

Available in Red or Black this high temperature Silicone Coated Glass fire sleeves are designed to protect hoses from the hazards of high heat and occasional flame. It protects continuously to 260°C and will withstand a molten splash at 1200°C. Made of knitted fiberglass yarns in a flexible substrate, it is then coated with a high grade silicone rubber and conforms with ASTM D-578, UL 94 Flammability Test: V1, UL 1441 Flammability VW-1.

Spring Guard Protection Sleeve

Full length or partial length stainless steel external spring guards can be fitted to increase the hose life cycle by protecting the outer cover from abrasion and acting as a bend restrictor. Often used in place of rubber or polypropylene covers which are limited on working temperatures.

Spiral Guard

A lightweight HDPE (High Density Poly Ethylene) flat section Anti-Static spiral guard provides excellent hose longevity when the application requires aggressive use in chemical applications when being dragged on the floor. Can be fitted to all hoses up to 4” outside diameter but is limited to a maximum hose operating temperature of +110c when external temperatures are ambient.

Whip Checks

Whip-checks provide health and safety compliance where extremely high pressures are used as they stop high pressure hoses from causing serious harm or death to operators. Can be fitted in order to help restrain hoses that have the potential to whip. Whip checks are a vital safety product for any high pressure hose application.

PTFE – Did you know?

Well, what is PTFE? Polytetrafluoroethylene, commonly known as PTFE or Teflon®, is a synthetic fluoropolymer which comprises of carbon atoms, each one linked to two fluorine atoms. As a fluorocarbon, PTFE has a high molecular weight which consists of fluorine atoms surrounding and protecting the carbon chain, thus creating the unique attributes that it is known for. PTFE has a melting point of 327°c, can maintain high strength, toughness and self-lubrication at temperatures as low as -268°c and has great flexibility at temperatures above -79°c.

Water and friction resistance

PTFE is a hydrophobic material meaning that neither water nor other water containing substances can wet it therefore making it superior to many other hoses used for the same or similar applications. As well as this, PTFE is also one of the lowest coefficients of friction against any solid which makes it extremely easy to use in a hose application as it can be dragged across a surface with ease.

Easily cleanable and unrivalled temperature range

PTFE has found itself a lot of uses, one example is in cooking where it is used as a non-stick surface for pans and where it also has to resist very high temperatures. This example can be used as a representation for how well PTFE performs as a hose liner material as its non-stick surface makes it easily cleaned as well as being able to resist a temperature range of -150°c to +260°c, which far outperforms any other rubber or plastic material.

Chemical resistance

Perhaps its most famous attribute is PTFE’s extremely high resistance to chemicals and corrosives. There are only a handful of scenarios where PTFE would not be the first choice regarding a corrosive or chemical application and these are extremely unusual scenarios such as Fluorine gas at a high temperature or boiling sodium metal. Apart from these, PTFE performs considerably well in many chemical hose applications and should be the first choice when choosing a hose for your application.

Popular PTFE Lined Hoses

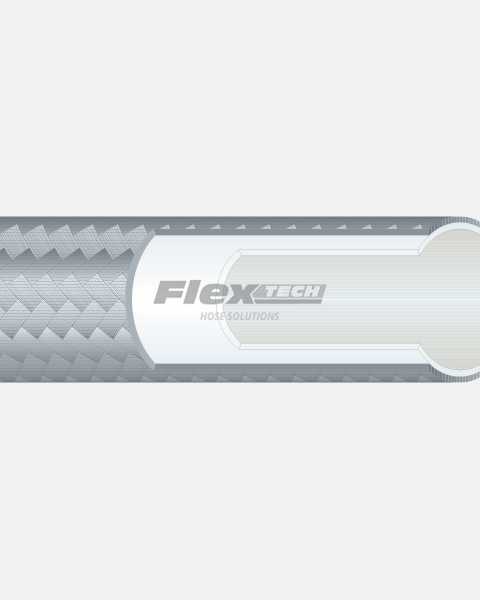

T6100 | PTFE Lined Hose Assemblies

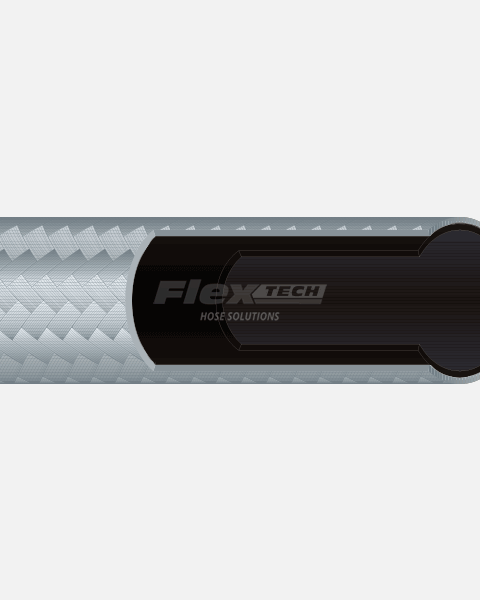

T6110 | FDA Antistatic PTFE Hose Assemblies

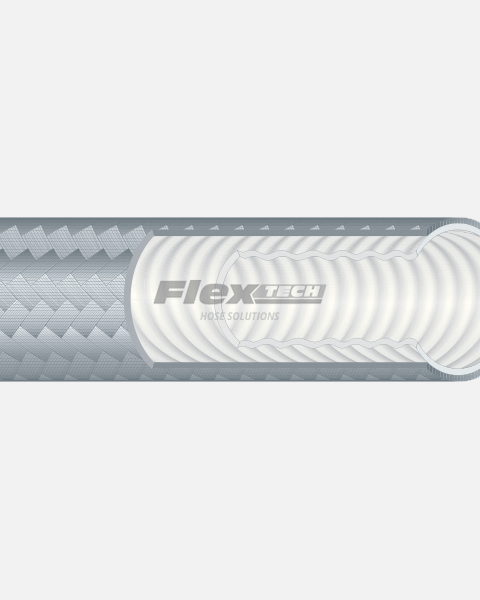

T6310 | EasyCrimp Convoluted PTFE Hose Assemblies

T6320 | Easy Crimp Convoluted Antistatic PTFE Hose

T6400 | Convoluted PTFE Hose (Teflon®)

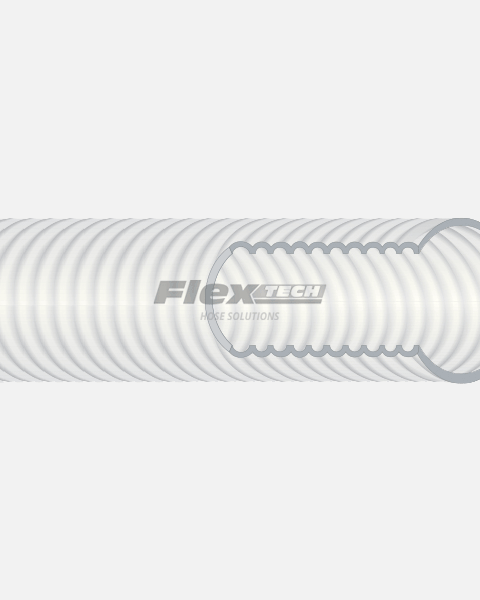

T6425 | Polypropylene covered Convoluted PTFE Hose

T6436 | Vacuum Resistant PTFE Hose for Aggressive Chemicals

T6451 | Castellated PTFE Hose Assemblies