Composite Hose Assemblies - Composite Hoses

What is a Composite Hose Assembly?

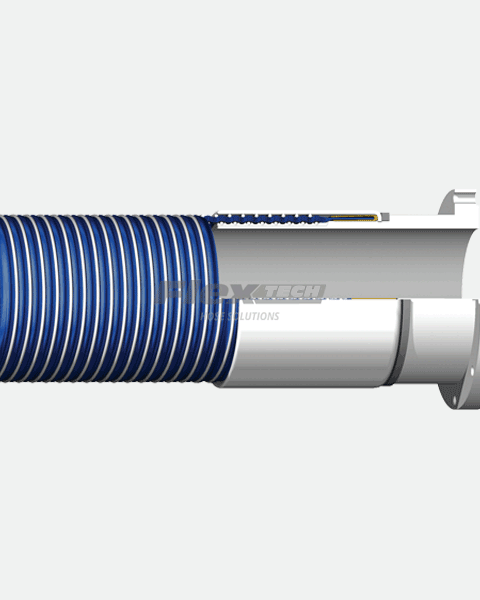

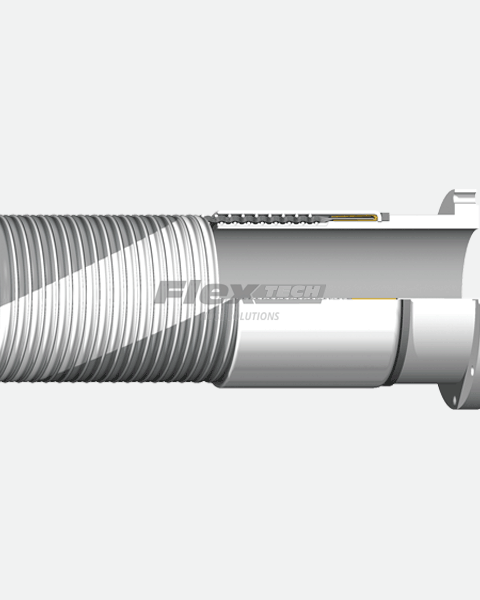

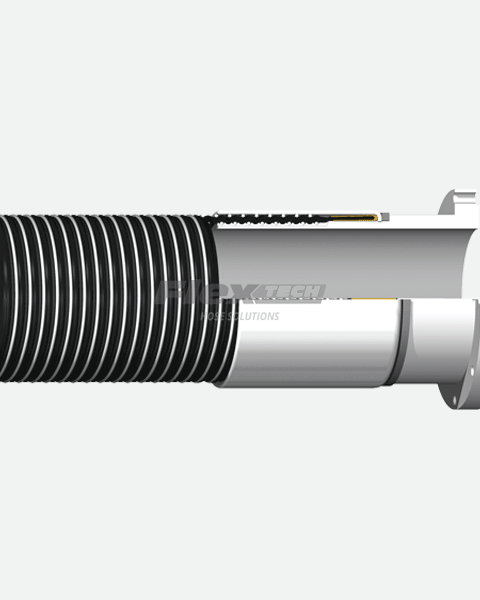

Flextech’s composite hose assemblies are manufactured from advanced composite materials in accordance with the strictest safety guidelines and quality standards. They provide optimum performance during critical and hazardous fuelling operations, chemical transfers, food transfer and loading of liquids. The blend of polymer liners, outer wire and polypropylene cover results in a composite hose with a vast array of benefits.

For an overview of all our hose assemblies, see our main hose assemblies page.

Composite hoses are flexible even with internal dimensions of 250mm, enabling use in a diverse range of situations both on land and at sea. Their medium weight strikes the ideal balance between easy handling and durability, with Flextech’s composite hoses resistant to wear, weathering and corrosion. A choice of wire reinforcement including hot zinc dipped galvanised steel and stainless steel coils strengthen the hose without corroding or creating static. The outer liner can be supplied in glow in the dark striped designs to provide visibility and easy identification at night.

Our hoses provide optimum performance during critical and hazardous fuelling operations, chemical transfers, food transfer and loading of liquids. The blend of polymer liners, outer wire and polypropylene cover results in a composite hose with a vast array of benefits.

Each composite assembly complies with BS5842, with marine variants meeting US Coast Guard and IMO regulations. They are pressure tested to 1.5 times their maximum working pressure and are checked for electrical continuity to ensure satisfactory resistance. The rubber swage seals are made from conductive rubber with dry seal end connections provided for complete safety and functionality.

Composite hoses are completely customisable, with lengths available up to 40m and internal sizes from 25mm to 250mm. A whole range of end connections are available including camlock couplings, valves and pressure fittings, fitted to the hose using Flextech’s advanced production methods.