EPDM Lined Rubber Hoses - EPDM Rubber Tubing

What is an EPDM lined hose assembly?

EPDM (Ethylene Propylene Diene Monomer) lined hose assemblies are types of rubber hoses designed for applications requiring excellent resistance to a wide range of chemicals, weathering, and temperature variations. The EPDM lining, made from the synthetic rubber EPDM, imparts unique properties to the hose assembly that make it suitable for various industries and applications, from food, beverage to chemical and steam.

EPDM tubing and hosing is synthetic rubber constructed from a tough and durable compound which is suitable for high temperature applications whilst being resistant to degradation and weathering from UV light from the sun, adverse temperatures, poor weather and ozone. EPDM rubber is versatile and available in a vast range of colours, making it the ideal sleeve material for hoses of all shapes and sizes, but also makes an effective liner for suction and delivery of hot water, steam, coolant and wine, fruit juices and soft drinks.

As EPDM is non-toxic, our rubber hoses are suitable for use in environments or cases with a high concentration of humans. Our EPDM lined steel hoses are designed for use in buildings to service ceilings, fan coils, heating and plumbing and are approved by the WRAS, the Water Regulations Advisory Scheme, in recognition that they do not contaminate the water supply. Our EPDM lined suction and delivery hoses for wine, fruit juices and soft drinks are FDA approved to show they do not pass on odour or taste to the product they contain. Its resistance to alcohol and other polar materials such as phosphate esters and ketones stops corrosion and other deterioration and makes EPDM rubber hosing durable and reliable.

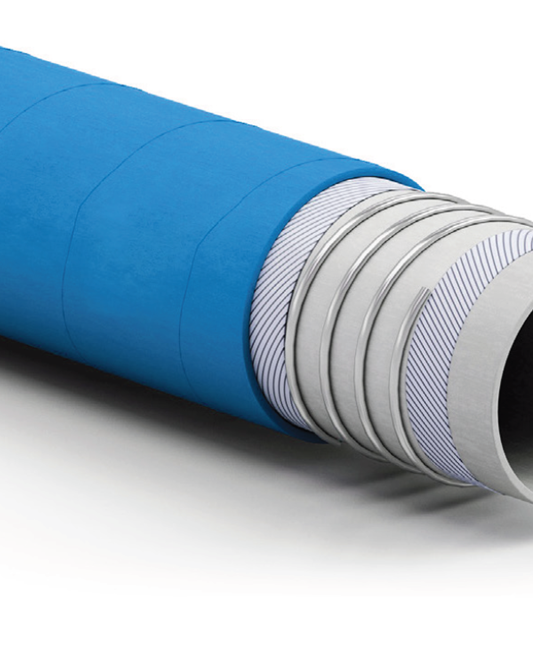

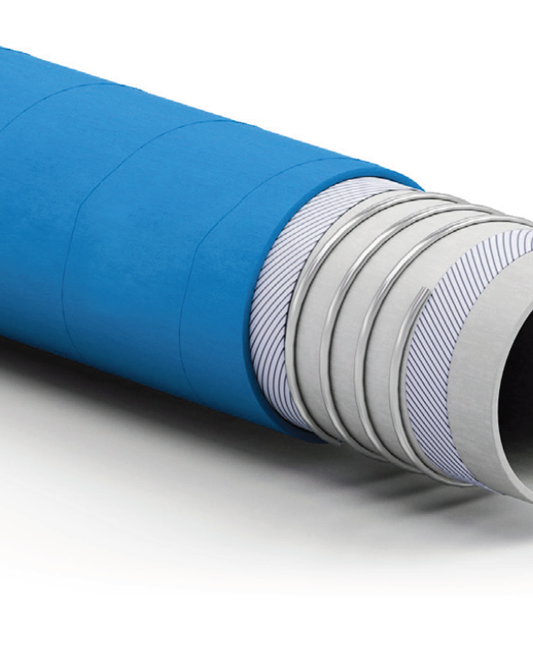

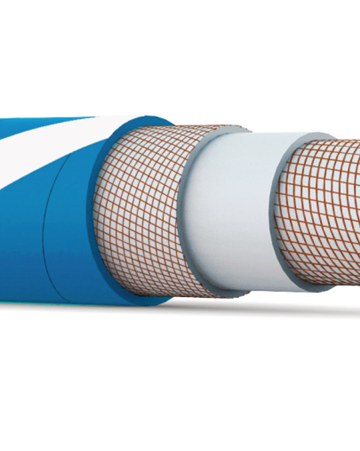

EPDM can be enforced with a high strength synthetic pile coating / braiding or a tight fitting steel or nylon spiral to provide crush and kink resistance. These braids help provide an excellent bend radius and flexibility without twisting or catching. Each end of the hose can be fitted out with your end connection of choice, from standard food and beverage couplings to specialist steam and chemical tank threads and clamps made from 316L stainless steel. Internal diameters from 1/2” to 4” offer allow you to get the correct throughput for your hose contents with no loss of pressure or unwanted bulging.

Here are the key features and benefits of EPDM lined hose assemblies:

- Chemical Resistance: EPDM is known for its outstanding resistance to a variety of chemicals, including acids, alkalis, detergents, and many solvents. This chemical resistance makes EPDM lined hoses suitable for applications in industries such as chemicals, petrochemicals, food and beverage, and steam.

- Temperature Tolerance: EPDM lined hose assemblies can handle a wide temperature range, from sub-zero temperatures to elevated temperatures. This versatility allows their use in both cold and hot environments.

- Steam Compatibility: EPDM lined hoses are often used in steam applications due to their resistance to high temperatures and steam. They can safely handle both dry and wet steam.

- Versatility: EPDM lined hose assemblies are utilized in a wide range of industries and applications, from automotive cooling systems and industrial machinery to HVAC systems and food processing.