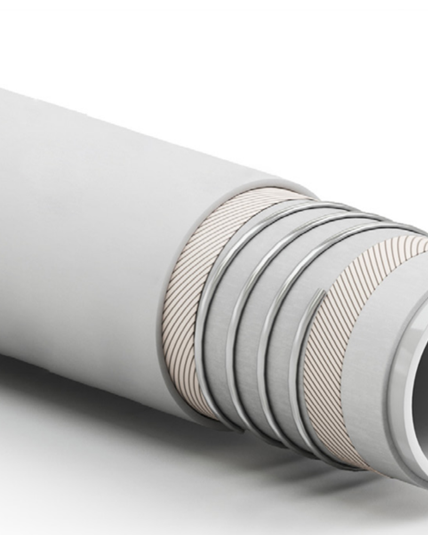

Fluoropolymer Hose Assemblies - Fluoropolymer Hoses

What is a fluoropolymer lined hose assembly?

Flextech manufacture bespoke Fluoropolymer industrial hoses in over 25 different variants with an unlimited number of customisation options including diameter, end connection, colour, reinforcement, cover and liner to suit your exact requirements. Some common fluoropolymers used for hose liners include PTFE (polytetrafluoroethylene), FEP (fluorinated ethylene propylene), and PFA (perfluoroalkoxy). Each type has its own set of properties and advantages, and the choice depends on the specific requirements of the application.

Fluoropolymers are a group of synthetic polymers that are known for their exceptional chemical resistance, thermal stability, low friction, and electrical insulating properties. These qualities make them highly suitable for a wide range of applications, including the use of fluoropolymer liners in flexible hose assemblies. Here's some more information about their use:

- Chemical Resistance: One of the most significant advantages of using fluoropolymers as liners in flexible hose assemblies is their excellent resistance to a wide range of chemicals and solvents. They can handle most aggressive and corrosive fluids without degrading or deteriorating, making them ideal for conveying substances that might cause damage to other materials.

- Temperature Stability: Fluoropolymers are capable of withstanding extreme temperatures, both high and low. They can maintain their properties and structural integrity in conditions ranging from cryogenic temperatures to elevated temperatures, which is crucial in applications where temperature fluctuations are common.

- Non-Stick Properties: Fluoropolymers have a low coefficient of friction, which gives them excellent non-stick properties. This property is particularly useful in applications where the transported materials may tend to adhere to the hose surface, such as in the food processing or pharmaceutical industries.

- Flexibility: Despite their robust chemical and thermal properties, fluoropolymer liners can still offer flexibility and ease of use in flexible hose assemblies. This combination of flexibility and durability makes them suitable for various applications where hoses need to bend, twist, or move in complex ways.

- Electrical Insulation: Fluoropolymers with antistatic compounds are excellent electrical insulators, which makes them suitable for applications where electrical continuity must be ensured. This is particularly important in cases where the fluid being transported is electrically conductive or in industries where electrical safety is a concern or ATEX environments.

- Purity and Cleanability: Fluoropolymers are often chosen for applications that require high levels of purity, such as in the pharmaceutical and food industries. These polymers are highly inert and do not leach contaminants into the transported fluids. They are also easy to clean due to their non-stick properties.

- Applications: Fluoropolymer-lined flexible hose assemblies find applications in various industries, including chemical processing, pharmaceuticals, food and beverage, semiconductor manufacturing, automotive, aerospace, and more. They are used for conveying aggressive chemicals, high-purity fluids, gases, and even abrasive materials.

Overall, the use of fluoropolymer liners in flexible hose assemblies provides a reliable and versatile solution for industries that demand exceptional chemical resistance, high purity, and robust performance in challenging environments.