Food Grade Hoses - Food Safe Hoses

Food Grade Hoses - Food Safe Hoses

When it comes to food production, the safety and quality of your hoses is paramount. That's why, at Flextech, we offer a wide range of food-grade hoses and food grade hose assemblies designed to meet the highest standards of hygiene and safety.

Our food safe hoses are suitable for a variety of applications, from food processing to water transfer, making them a versatile choice for any food and beverage related industry.

Whether you need a non-toxic food-grade water hose for your production line or a premium food-grade hose for brewery, distillery, dairy or pharmaceutical uses, our hose range has you covered. Our products are lead-free and manufactured to the highest standards, to give you complete peace of mind when it comes to food safety.

With a range of hose sizes and fittings available and an easy filtering system to help you select the right hose product on our website, it’s easy to find the perfect food-grade hose for your specific needs. Our hoses are designed to withstand high pressure and are easy to clean, making them the ideal choice for any food-related application.

Food Grade Hose Collection

Dairy Food Grade Hoses

Pharmaceutical Food Grade Hoses

T4210 | PharmaSil™ Braided Silicone Hose

T4201 | PHARMAFLEX® Pharmaceutical Suction & Delivery Hose

T5656 | Pharmafluor PTFE Lined EN-12115 FDA Rubber Hose

T6450 | PTFE Hose Assemblies

T6420 | Flexible Food Grade PTFE Hose to FDA 21 CFR 177.1550

T6110 | FDA Antistatic PTFE Hose Assemblies

T6600M | Metric PTFE Tubing (Teflon® Tube)

T3350-3318 | Food & Pharma Polyurethane Ducting

PTFE Food Grade Hoses

T5656 | Pharmafluor PTFE Lined EN-12115 FDA Rubber Hose

T6450 | PTFE Hose Assemblies

T6400 | Convoluted PTFE Hose (Teflon®)

T6600M | Metric PTFE Tubing (Teflon® Tube)

T6451 | Castellated PTFE Hose Assemblies

T6110 | FDA Antistatic PTFE Hose Assemblies

T6310 | EasyCrimp Convoluted PTFE Hose Assemblies

T6435 | Polypropylene Braided Convoluted Antistatic PTFE Hose

PVC Food Grade Hoses

T1200 | Braidflex™ Multipurpose Braided PVC Hose

T1900 | FlexVac™ Vacuum/Crush Resistant Multipurpose Hose

T1690 | Flexhose™ Food Multipurpose PVC Suction & Delivery Hose

T1690R | Flexhose™ Beverage Special Duty PVC Wine & Juice Hose

T1700 | Flexhose™ Food-AS Antistatic, Dry Foodstuffs PVC Suction & Delivery Hose

T1755 | Flexhose™ HD Heavy Duty Multipurpose PVC Suction & Delivery Hose

T1220 | Thermoclean® 100 PVC Industrial Cleaning Hose

T1220S | Super Thermoclean® 100 PVC Industrial Cleaning Hose

Food-Grade Hose - FAQs - Understanding Food-Grade Hoses: Essential for Safe Food and Beverage Handling

In industries that handle food, beverages, or pharmaceuticals, maintaining high standards of cleanliness and product integrity is critical. This is where food-grade hoses come in—specialized hoses designed for the safe transfer of consumable goods without risking contamination or compromising product quality. Let's explore what makes a food-grade hose unique, the materials it's made from, and its essential applications

What is a food grade hose?

A food-grade hose is a specially designed hose used to transport consumable products safely, made from compound materials that help prevent contamination and meet food safety standards. Unlike standard hoses, food-grade hoses avoid affecting the flavour, colour, or quality of products. These hoses are widely used across industries such as brewing, dairy processing, confectionery, fast food, soft drinks, and alcohol, essentially supporting any application involving products for human or animal consumption.

Due to their construction, typically from varying grades of silicone, rubber, or PTFE, food-grade hoses ensure no harmful chemicals, Odors, or tastes leach into consumable products, preserving their natural flavour and aroma. They are often also highly flexible and durable, able to withstand varied temperatures and handle liquids, pastes, or vicious products. With smooth internal liners and special hygienically fitted end connections all help to minimize bacterial buildup, these hoses are easier to clean and maintain. Their resistance to oils, fats, acids, and other potentially degrading substances enables safe, efficient transport, maintaining product integrity and consumer safety

Why Food-Grade Hoses Matter

The integrity of consumable products is paramount in industries dealing with food and beverages. Food-grade hoses help prevent contamination and make it easier to comply with regulatory standards, such as those set by the U.S. FDA or European food safety authorities. With their combination of durability, cleanliness, and resistance to contamination, food-grade hoses are essential for maintaining quality and ensuring safe production processes across food and beverage sectors.

Which applications and industries can food safe hoses be used in?

Food quality hoses are essential in industries where the safe production and transport of consumable products are a priority. They are utilized in various applications to ensure hygiene, quality, and regulatory compliance. Food-grade hoses find critical applications across multiple sectors, including:

Food and Beverage Processing

Dairy Processing: Transporting milk, cream, yogurt, and other dairy products.

Beverages: Used in breweries, wineries, and distilleries for beer, wine, and other alcoholic or non-alcoholic drinks.

Confectionery: Moving liquid chocolate, syrups, and other sweet products.

Meat and Seafood Processing: For rinsing, marinating, and other processes requiring food-safe handling.

Pharmaceuticals and Cosmetics

Pharmaceuticals: Safely transferring liquids, gels, and semi-solid ingredients in pharmaceutical production.

Cosmetics: Moving lotions, creams, and other personal care products where hygiene standards are similar to food handling.

Agriculture and Dairy Farms

Milking Equipment: Used on dairy farms to transport milk from cows to storage tanks.

Irrigation for Edible Crops: Ensuring hoses used in crop irrigation meet safety standards to prevent contamination.

Food Production

Artisanal Food Production: operations producing jams, sauces, oils, and similar products often use food-grade hoses.

Industrial Food Production Facilities

Bulk Ingredient Transfer: Moving large quantities of ingredients such as oils, sauces, syrups, and grains.

Packaging and Filling Machines: Ensuring hygienic filling of bottles, jars, or bags with food products.

Cleaning and Sanitation in Food Facilities

Food-grade hoses are also used in cleaning applications, especially for rinsing equipment and areas that require sanitary-grade hoses to prevent cross-contamination.

Each industry has specific requirements, so food-safe hoses may vary in material, temperature tolerance, flexibility, and resistance to oils, acids, or chemicals to match the application’s demands.

What are the benefits of using food safe hoses?

Food-safe hoses offer numerous benefits for maintaining the quality and safety of food products during processing and transfer. Designed for durability, these hoses can withstand high temperatures, pressures, and abrasion typically encountered in food processing facilities. With a wide range of pressure capacities, food-safe hoses are suitable for many applications found throughout the production process. Additionally, their odourless and tasteless design helps preserve the food's natural flavours and aroma, while their flexibility and ease of installation reduce the risks of contamination.

In addition to safety and quality, food-safe hoses are vital for regulatory compliance, meeting stringent standards such as FDA and EU regulations. Their ability to resist high and low temperatures makes them ideal for applications ranging from pasteurization to refrigeration. These hoses are also resistant to oils, fats, and chemicals, ensuring they can handle various ingredients without degrading. The smooth inner surface of food-safe hoses minimizes bacterial buildup, making cleaning easier and preventing contamination. Their flexibility allows for easy handling or flexibility required in tight spaces, while their durability reduces maintenance needs, leading to increased efficiency and reduced downtime in food production environments. Overall, food-safe hoses are a valuable investment for businesses aiming to uphold safety standards and protect product quality.

What sizes are available for food grade hoses?

At Flextech we offer a diverse range of food-grade hoses in various sizes tailored to meet the needs of different applications within the food and beverage industry. Our hoses are available with internal diameters starting from ¼” (6mm) up to 4” (102mm), accommodating both small-scale operations and larger industrial processes. Additionally, we offer customization in lengths for all our food quality Hose Assemblies which are manufactured on site from as short as 250mm long right up to a maximum of 40 Metres Long.

What is the difference between food quality hoses and food grade hoses?

The terms "food quality" hoses and "food grade" hoses often create confusion, as they imply different standards and applications. Food-grade hoses are specifically engineered and tested to comply with regulatory standards set by authorities such as the FDA or EU for direct contact with consumable products. These hoses carry formal certifications that ensure the compounds used in the manufacturing process comply with the standards.

In contrast, food-quality hoses refer to those that may be suitable for certain food-related uses but do not necessarily meet stringent food safety regulations. While they are manufactured to high-quality standards, food-quality hoses might lack formal certifications for direct food contact and are typically used in lower-risk applications, such as water transport or cleaning in food environments, where direct contact with food is limited. The key difference lies in certification and compliance: food-grade hoses are designed for direct contact with consumable goods and are better suited for stringent safety requirements, while food-quality hoses are more appropriate for general tasks within food environments where strict certification is less critical.

Can food grade hoses be used in dairy operations?

Yes, our Food-grade hoses are highly suitable for use in many food & beverage processing operations including dairy operations. These hoses are made from material compounds that comply with strict hygiene and safety regulations set by organizations. Their construction and design varies but essentially allows them to withstand various temperatures, pressures and products, making them ideal for the demanding applications they are used in.

For example, our Dairyflex hoses are tailored to transport milk, cream, yogurt, and fatty foods while reducing the risk of bacterial growth and contamination. Key advantages of using food-grade hoses in dairy operations include compliance with food safety standards, non-toxic and taste-neutral materials, high durability, and flexibility. Additionally, these hoses are easy to clean and sanitize due to their smooth inner linings, which help maintain sanitary conditions essential for processing perishable dairy products.

Overall, food-grade hoses meet the specific needs of dairy processing, ensuring the safety and quality of dairy products.

What standards and regulations do your food grade hoses comply with?

Food-grade hoses are regulated by various standards worldwide to ensure their safety and suitability for handling consumable products. Our food-grade hoses adhere to all relevant UK, European, and numerous international standards, including FDA 21 CFR 177.2600, which governs rubber articles for repeated use in food applications. Additionally, they comply with BfR D.M.21/03/73, are ADI free, and meet CE 1935/2004 standards. Furthermore, our hoses are phthalate-free and align with 3-A Sanitary Standards, USP Class VI (for Pharmaflex only), EU Pharmacopeia 3.1.9 (for Pharmaflex only), and BRCGS (British Retail Consortium Global Standards) of which Flextech are a member.

The compliance with these standards ensures that our food-grade hoses are safe for direct contact with food products, do not leach harmful substances, and maintain the quality of the food being handled. It is essential to verify specific certifications for each product to ensure compliance with regional regulations, especially when selecting hoses for food-related applications. By meeting these stringent safety standards, our hoses provide reliable and hygienic transport solutions across various industries, ensuring the safety of consumable goods in both domestic and international markets.

Here’s a list of the varying standards that some or all hoses must comply with, along with a brief summary of what each covers:

- FDA 21 CFR 177.1550: covers the use of materials ensuring they are safe and suitable for repeated use without leaching harmful substances.

- FDA 21 CFR 177.2600

Covers rubber articles intended for repeated use in contact with food, ensuring safety and non-toxicity. - BfR D.M.21/03/73

Regulates materials in food-contact applications in Germany, ensuring safety and compliance. - ADI Free

Ensures that materials are free from Animal Derived Ingredients that could pose a health risk in food applications. - CE 1935/2004

Ensures materials in contact with food are safe and do not release harmful substances or alter food quality. - Phthalate Free

Indicates that the materials used do not contain phthalates, which can be harmful to human health. - 3-A Sanitary Standard

Ensures that materials are easy to clean, non-toxic, and resistant to microbial growth, especially in dairy and food processing. - USP Class VI (Pharmaflex only)

Certifies that materials are suitable for medical applications, ensuring safety for human contact. - EU Pharmacopeia 3.1.9 (Pharmaflex only)

Provides standards for the quality and safety of pharmaceutical materials used in food applications. - BRCGS (British Retail Consortium Global Standards)

Ensures compliance with best practices for food safety and quality throughout the supply chain. - NSF 51

Ensures materials used in food processing equipment are safe for direct food contact. - NSF 61

Applicable to hoses used in potable water systems, ensuring they prevent contaminants. - EU Regulation 1935/2004

Ensures safety and quality of materials in contact with food, preventing harmful substance migration. - EU Regulation 10/2011

Governs plastic materials in contact with food, focusing on migration limits to ensure safety. - ISO 846

Provides guidelines on antimicrobial resistance relevant to food-grade materials. - REACH

Ensures that chemicals used in products meet environmental and health safety standards in the EU. - RoHS

Ensures that products are free from hazardous substances like lead and mercury. - Codex Alimentarius

International food safety guidelines established by the FAO and WHO to ensure safe food practices globally.

Are your hoses flexible and easy to install?

Absolutely! Our food-grade hoses are engineered for flexibility and straightforward installation, often coming with various hygienically fitted end connections to enhance usability. For instance, the Dairyflex Lite hose is noted for its "very flexible" and "light handling" qualities, making it ideal for a range of applications.

In general, food-grade hoses are designed to be flexible and easy to install, making them perfect for dynamic environments in the food and beverage industry. This flexibility is essential for applications that require frequent movement, rapid setup, and compatibility with complex configurations. Here’s why our food-grade hoses stand out in terms of flexibility and ease of use.

What temperature ranges can your food safe hoses withstand?

Our food-grade hoses are designed to endure a broad spectrum of temperatures. For example, the Dairyflex Lite hose can operate effectively from -40°C to +100°C, with intermittent usage up to 130°C for sterilisation. Food-safe hoses come in various materials that accommodate different temperature extremes, making them suitable for a wide array of food and beverage applications. Here’s a summary of flextech’s typical temperature ranges for our food safe hose materials:

- Pharmaflex - Silicone Hoses

- Temperature Range: Approximately -60°C (-76°F) to +200°C (392°F)

- Applications: Ideal for extreme cold and high-heat processes, pasteurization, or hot liquid transfer.

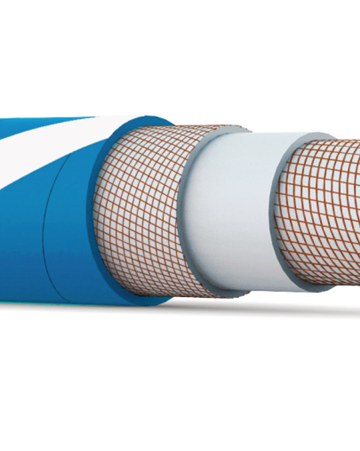

- Multiflex - Rubber Hoses (EPDM)

- Temperature Range: -40°C (-40°F) to +120°C (248°F)

- Applications: Commonly used for all food and beverage transfer up to 40% alcohol content, as they can handle moderate heat and are durable against oils and fats.

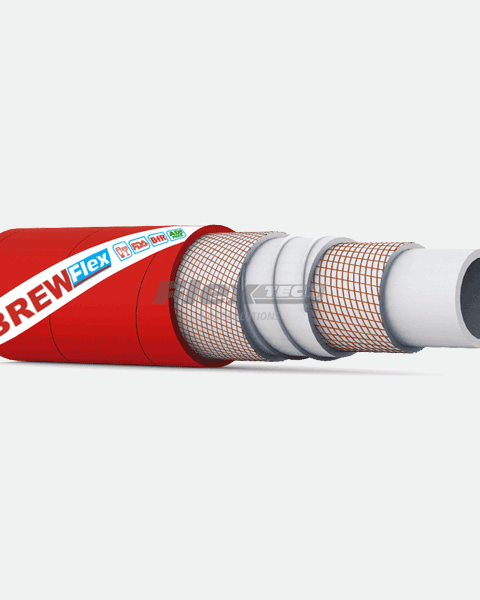

- Brewflex - Rubber Hoses (EPDM)

- Temperature Range: -40°C (-40°F) to +120°C (248°F)

- Applications: Commonly used for brewery and alcoholic transfer up to +96% alcohol but not suitable for fatty foods.

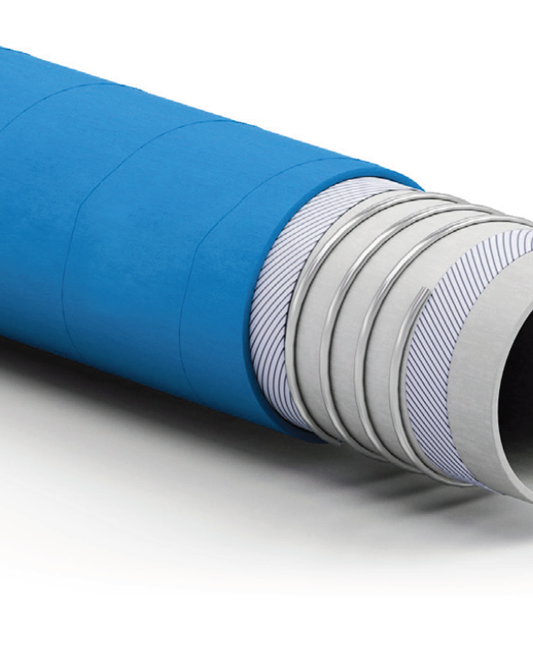

- Dairyflex - Rubber Hoses (Nitrile)

- Temperature Range: -40°C (-40°F) to +100°C (212°F)

- Applications: Commonly used for dairy and non-alcoholic beverage transfer, as they are durable against oils and fats.

- Steamflex - Rubber Hoses (EPDM)

- Temperature Range: -40°C (-40°F) to +170°C (338°F)

- Applications: Commonly used for wash down and sterilizing production areas.

- PTFEflex - Teflon (PTFE) Hoses

- Temperature Range: -60°C (-76°F) to +260°C (500°F)

- Applications: Excellent for high-temperature and high-purity applications, as PTFE is chemically inert and can withstand both hot and cold extremes with excellent flexibility and pressure resistance.

- Flexvac - Polyurethane Hoses

- Temperature Range: -35°C (-31°F) to +80°C (176°F)

- Applications: Typically used for dry food products or low-temperature liquid transfers due to their abrasion resistance and flexibility.

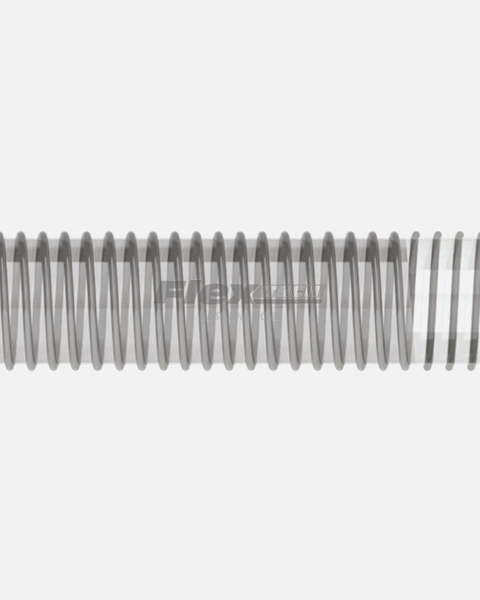

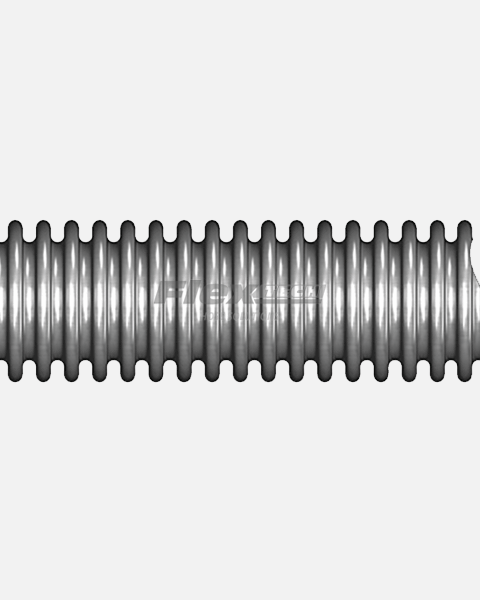

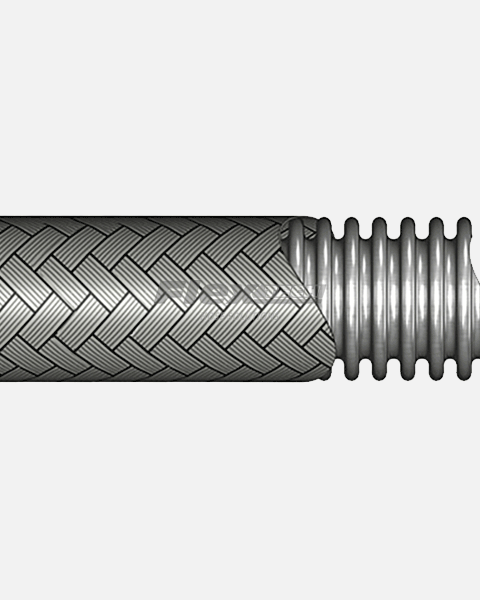

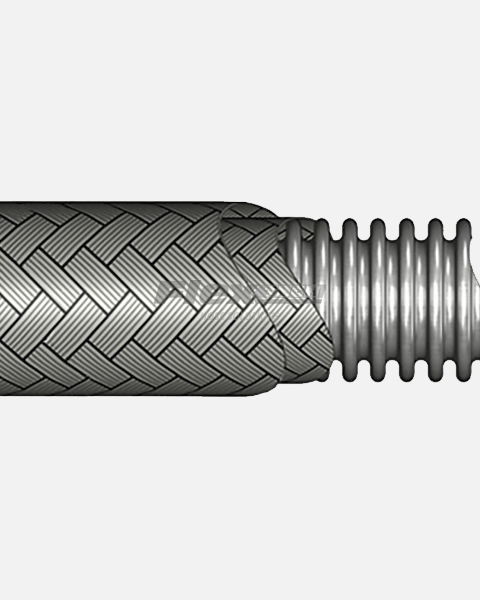

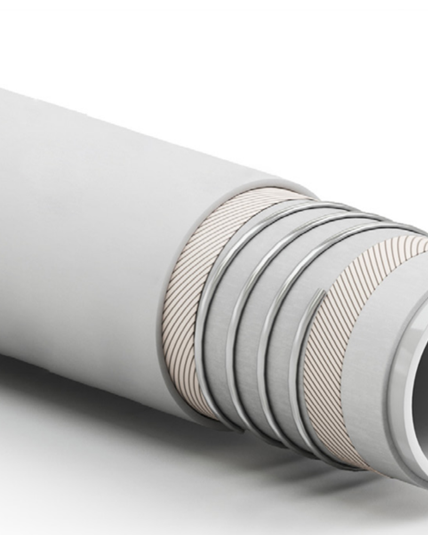

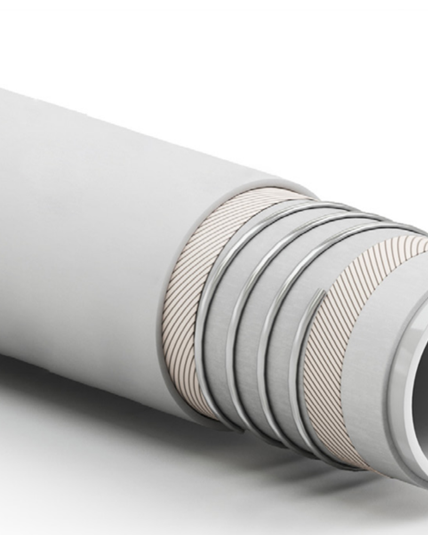

- Metalflex - Stainless Steel Metallic Hoses

- Temperature Range: -200°C (-328°F) to +600°C (1112°F)

- Applications: Often used in high-temperature applications, such as hot liquid or steam transfer, requiring both flexibility and temperature tolerance.

- Flexvac - PVC (Polyvinyl Chloride) Hoses

- Temperature Range: Approximately -20°C (-4°F) to +65°C (149°F)

- Applications: Suitable for general use with room-temperature foods and liquids.

Summary

Most food-safe hoses can cover a wide range from -40°F to 500°F (-40°C to 260°C), depending on the material. Options are available for both low-temperature and high-heat environments, making it crucial to select the correct hose material based on your specific temperature requirements to ensure durability, safety, and optimal performance.

What maintenance is required for your food grade hoses?

To ensure the longevity and performance of food-grade hoses, regular maintenance is essential. Here are some key maintenance practices to follow:

- Hose Health Check

- Utilize Flextech’s Professional Assessment: Consider utilizing a Hose Health Check service and on-line hose management software to identify potential issues before they lead to failures. This service includes thorough inspections and testing to ensure hoses are in good condition. Simply contact us to arrange this.

- Inspection

- Visual Inspections: Regularly check the hoses for any signs of wear, damage, or abrasion, such as cracks, kinks, discoloration, or deterioration.

- Check Fittings and Connections: Ensure all fittings and connections are secure and leak-free. Replace any damaged or worn fittings immediately.

- Replacement Schedule

- Track Usage: Maintain records of usage and maintenance to determine when hoses should be replaced. Regular inspections will help identify when a hose has reached the end of its service life.

- Regular Cleaning

- Routine Cleaning: Clean the hoses after each use to eliminate residues, bacteria, and contaminants. Use warm water combined with a mild detergent or food-safe cleaner.

- Sanitization: After cleaning, sanitize the hoses with an appropriate food-safe sanitizer to prevent microbial growth and maintain hygienic conditions. More information about cleaning and sanitization can be found here.

- Storage

- Proper Storage: Store hoses in a clean, dry location away from direct sunlight, extreme temperatures, or sharp objects that could cause damage.

- Avoiding Kinks and Twists: When storing, ensure hoses are not kinked or twisted to prevent weak points that could lead to failure.

- Temperature Monitoring

- Adhere to Temperature Limits: Always use hoses within their specified temperature range to avoid damage and potential failure. Avoid Extreme Temperatures: When not in use, keep hoses away from extreme temperatures that could cause degradation.

Professional Servicing

- Consult Manufacturer Guidelines: Follow the maintenance and care guidelines provided by the hose manufacturer, including recommendations for cleaning agents, storage conditions, and inspection frequencies.

Summary

Regular cleaning, inspection, proper storage, and adherence to usage guidelines are crucial for maintaining food-grade hoses. Additionally, incorporating a Hose Health Check can help proactively identify issues. By following these practices, you can extend the lifespan of the hoses, ensure the safety of the products they handle, and minimize the risk of contamination or equipment failure in food processing environments.

What is the lifespan of your food grade hoses?

The lifespan of our food-grade hoses is influenced by several factors, including usage patterns, maintenance routines, and environmental conditions and application. With proper maintenance and regular inspections, the lifespan of these hoses can be significantly extended. Moreover, our hoses are engineered to meet rigorous safety and quality standards, ensuring they remain durable and reliable over time. It is important to always sterilize your hoses to the recommended CIP guidelines as failure to do this will always result in premature failure. Here is a general guideline on the longevity of hoses in general.

1. Silicone Hoses • Lifespan: Typically 3 to 7 years. • Factors: Durability in high-temperature applications contributes to a longer lifespan, but exposure to UV light or ozone can degrade silicone over time.

2. PVC (Polyvinyl Chloride) Hoses • Lifespan: Generally 2 to 4 years. • Factors: While resistant to many chemicals, PVC hoses will not withstand extreme temperatures, regular flexing or heavy mechanical stress, affecting their longevity.

3. Rubber Hoses (e.g., Nitrile, EPDM) • Lifespan: Approximately 3 to 7 years, depending on the rubber type and application. • Factors: The ability to resist oils and fats contributes to longevity, but environmental factors like ozone exposure will reduce lifespan.

4. Teflon (PTFE) Hoses • Lifespan: Can last up to 20 years or more. • Factors: Known for their chemical resistance and high-temperature capabilities, PTFE hoses tend to have a longer lifespan when properly maintained.

5. Polyurethane Hoses • Lifespan: Typically 2 to 5 years. • Factors: Durable and flexible, but exposure to extreme temperatures or abrasive materials can shorten their life.

6. Stainless Steel Metallic Hoses • Lifespan: Generally 5 to 15 years or more, depending on the specific design and materials used. • Factors: Resistant to high temperatures and pressures, but the lifespan can be drastically reduced when flexing cycles are regular.

Factors Affecting Lifespan

• Frequency of Use: Hoses used in high-frequency applications may wear out more quickly than those used sporadically.

• Cleaning and Maintenance: Regular cleaning and proper storage can significantly extend the lifespan of food-grade hoses.

• Environmental Conditions: Exposure to UV light, extreme temperatures, and harsh chemicals can negatively impact hose longevity.

• Application: Hoses used in demanding environments (high pressure, hot liquids) may have shorter lifespans compared to those in less stressful conditions.

Summary

While food-grade hoses can last anywhere from 3 to over 10 years, regular maintenance, proper usage, and storage practices play critical roles in maximizing their lifespan. Monitoring for signs of wear and adhering to the manufacturer’s guidelines will help ensure the hoses remain effective and safe throughout their use.

What kind of warranty is provided with your premium food grade hoses?

We offer a 12-month warranty, subject to terms and conditions outlined here.