Metal Hose Assemblies - Stainless Steel Hoses

What is a Metallic hose assembly?

Flextech’s flexible metallic hose assemblies are designed to meet the stringent temperature, pressure and vacuum service requirements found in a huge array of applications. Manufactured from high grade, flexible stainless steel, they also offer unique properties which include excellent chemical resistance and high temperature resistance. With operating temperatures as low as -200°c and as high as +600°c (with a peak point of 800°c in some circumstances), Flextech’s metallic hoses offer performance and reliability in all situations.

Metallic Hose Assemblies

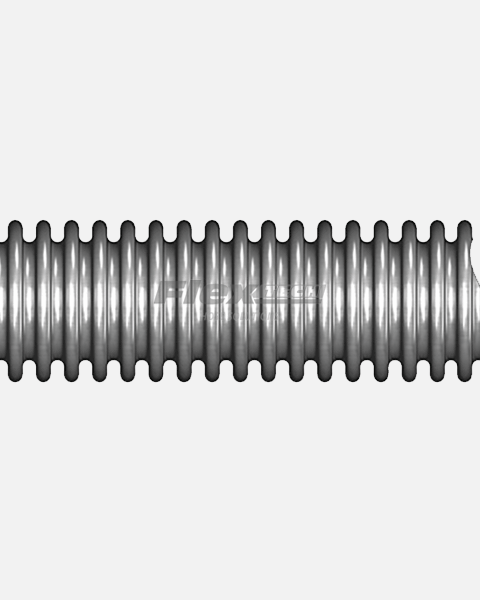

Available as convoluted bore with an assortment of grades, covers & end terminations, these metal hoses are ideally suited for gas supply and transfer of steam, chemicals, food processing, hot water systems, cryogenics and full vacuum applications. Our metallic hoses are able to withstand up to 50,000 flex cycles and are manufactured to ISO10380, the current international standard for corrugated metal hoses and hose assemblies.

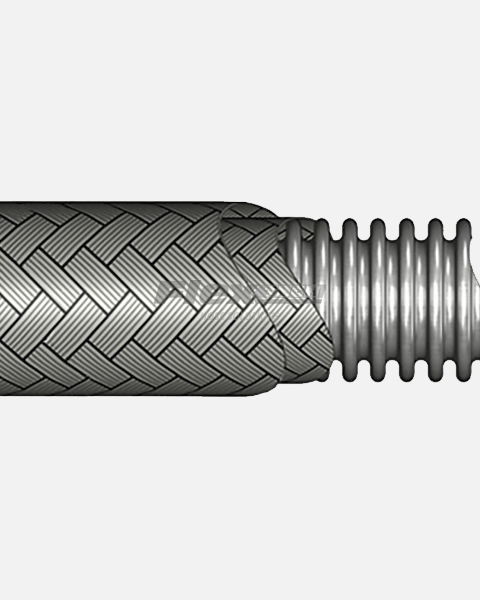

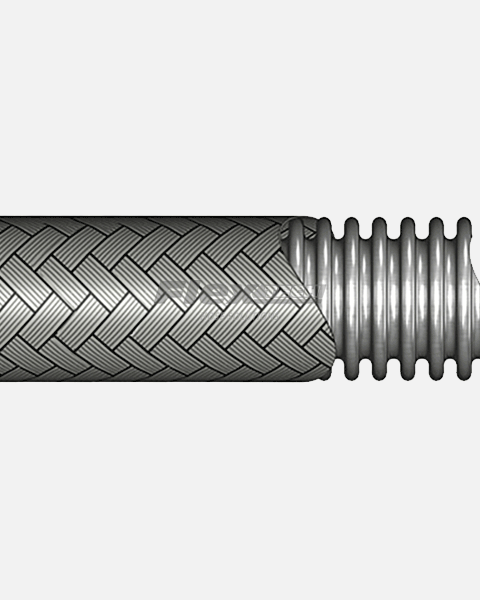

Typically, our full stainless steel braided hoses consist of an AISI 321 or 316 grade liner within a 304 or 316 grade stainless steel braid. This braid can be reinforced as a double or even triple braid for maximum protection or covered in silicone, EPDM, a fire sleeve or flexible insulative material. Internal dimensions for all of our metallic hosing range from narrow 6mm diameter to large bore 250mm diameters. Pressure ratings range from 40 bar BP with 880 bar BP high pressure capacity.

Typical applications of our metallic hoses:

- High Temperature Hydraulic Oils in machinery, vehicles and engineering

- Steam, Chemicals and Petroleum products used in manufacturing, construction and energy

- Corrosive liquids & Gases in the chemical and medical industries

- Compressed Air & Pneumatic liners

- Cryogenic applications

- Food & Beverage production

- Nuclear plants and Steam lines

- Fluids associated with high temperature and pressure in paper and fabric plants,

- Specialist manufacturing including Tyre moulds and Textile Machinery

- Oil Refineries and Drilling Rigs / Platforms

- Toxic and corrosive applications.

Key features of Metallic hose assemblies

- Chemical compatibility

- Excellent temperature range

- Non-permeable

- Retains shape under full vacuum

- Flexible

The general rule of thumb is to use a metallic hose when no other hose type will do. Flexible metallic hoses perform well in applications with extreme conditions or variables such as temperature extremes, diverse chemical compatibility or concerns around liquid permeation.