Smoothbore PTFE Hoses

What is a smoothbore PTFE hose assembly?

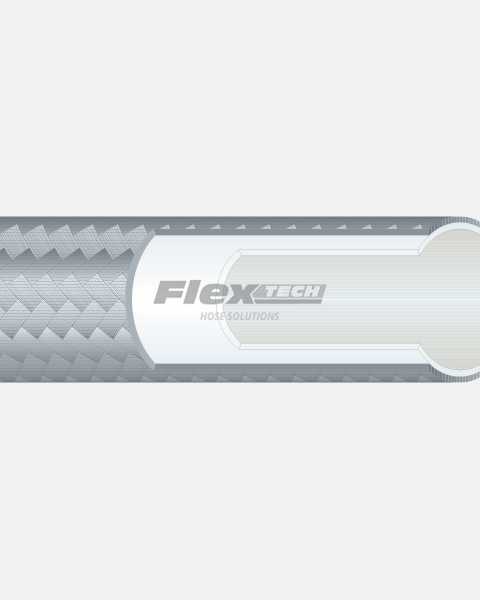

Smoothbore PTFE hoses feature a completely smooth liner without internal grooves, textures or convolutions on the inner surface of the hose. Smoothbore PTFE hoses consist of a non-stick Teflon liner reducing friction and stopping product transfer from sticking to the inner tube therefore eliminating potential blockages. Smoothbore PTFE hoses enable a high flow rate to be maintained even at low pressure and temperature, making them the perfect choice for transferring food, beverage, pharmaceuticals, gas & gaseous media, chemicals and steam.

Smoothbore PTFE lined hoses are formed from a single piece of extruded tubing which is then reinforced and covered with optional layers of stainless steel and/or aramid (Kevlar) over-braids. There are many options to customise Smoothbore PTFE hoses with additional covers including; platinum cured silicone, polyurethane, FEP, EPDM rubber and temperature resistant fire sleeves. These ensure that the finished smoothbore PTFE hose assemblies are fit for purpose solutions that meet and exceed application requirements.

Over-braids make the hose more able to withstand high pressure, repeated flexing cycles (up to 1 million) and increasing bend radius, providing a reliable solution for whichever material is passed through the hose. As PTFE is such a diverse and versatile material it is suitable for a wide range of industrial, gaseous, hygienic and specialist applications.

Industrial Smoothbore PTFE Hoses:

The lightweight properties of PTFE allow the smoothbore hoses to be reinforced with heavy walls, stainless steel braids or even kevlar whilst still retaining a relatively low mass. The heavy wall reduces permeation of products with a small molecular structure (such as high temperature fluids, petrochemicals and bio-chemical fluids) to an absolute minimum making issues from leaking of dangerous or valuable material very unlikely. When opting for a PTFE smoothbore hose with a double sintered wall such as the Flextech T6145 & T6160, molecules are further contained making these safe for gas procedures which present an element of risk such as cylinder charging, aerosol charing, high pressure gas and skydrol applications or within breathing apparatus. Further reinforcement from kevlar braid offers incredible strength and flexibility for situations where weight and reliability is key, such as motor racing and on aircraft. Other materials such as ETFE, PFA and FEP are great alternatives to PTFE hoses as they offer less permeability with specific gas applications.

Hygienic Smoothbore PTFE Hoses:

Our standard wall PTFE lined smoothbore hoses are FDA approved for use in food, medicine and beverage production, and adhere to a whole range of quality and sanitary standards including BS EN ISO 9001:2008, FDA 21 CFR 177.1550, 3A Sanitary Standards, SAE J1737, EN10204 and EN45014. As PTFE is chemically inert it does not pass on any odour or taste to the product contained within, and the ageing and weathering resistance ensures that the PTFE hose is ready to be used even after storage for a long time. Some of the hygienic hoses have a black PTFE anti-static lining alternative which is adherent to FDA 21 CFR 178.3297, so when working with gases, aerosols or charged particles in cleanrooms or production areas these will not pose a threat to those on the production line.

Castellated PTFE Hoses / Flexible Smoothbore PTFE Hoses

The castellated PTFE hose is a patented design whereby a heavy walled PTFE tube is manufactured in such a way that enables the tube inner to remain smooth whilst the outer of the tube is convoluted. This ensures an increased maximum bend radius’ for applications that demand high flow rates from a smoothbore PTFE hose in sizes ranging between ½” to 2”.

Custom PTFE Hose Design / Tafting:

Smoothbore PTFE hose assemblies are fitted with permanently swaged end connections providing a safe and reliable solution. End connections for our smoothbore PTFE hoses can also be customised and laser etched or engraved, with options including but not limited to triclovers, DIN, RJT, SMS, BSPT, IDF and ISS.

Smoothbore PTFE Hoses are also uniquely designed to be tafted, where the liner is extruded and flared over the face of an attached fitting to line the wetted parts with PTFE, preventing corrosion and ensuring hygiene standards by eliminating potential microbial buildup from product media conveyed through the hose which can cause batch contamination. PTFE tafting also provides the additional benefit of a singular extruded bore for the entire length of the hose, also known as full bore or through bore.